-

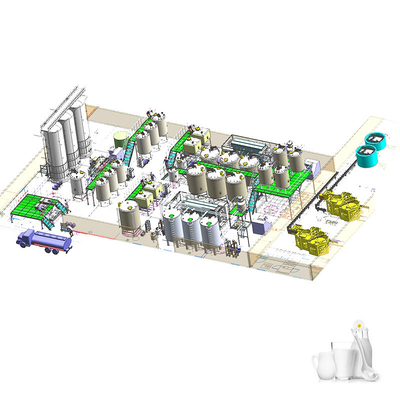

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

10000L / Day UHT Milk Processing Line With Milk Processing Unit 250 - 1000ml

| Place of Origin | CHINA |

|---|---|

| Brand Name | BEYOND |

| Certification | ISO 9001/SGS/CE/TUV |

| Model Number | BY-UT |

| Minimum Order Quantity | 1SET |

| Price | 100000USD-800000USD/set |

| Packaging Details | export standard packing, worthy for long distance sea shipping |

| Delivery Time | 80-100days upon the recipt of downpayment and confirmation of drawings |

| Payment Terms | T/T, L/C, west union |

| Supply Ability | 20 sets per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Flavored Milk, Grain Milk, Oats Milk | Capacity | 10000LPD |

|---|---|---|---|

| Power Supply | 380V 50hz | Space Required | 500-800sqm |

| Highlight | milk processing unit,milk production equipment |

||

10000L per day H UHT Tubular Sterilizing Milk Processing Machinery 250-1000ml

![]()

This UHT system adopts ultra high heat treatment to sterilize the liquid dairy products, tea drink or juice for the the aseptic filling production; the sterilize temperature is 137℃ holding for 3~5S, to remain the nature nutrition and flavor of the milk and juice;

This machine has the following characteristics: high heat reuse efficiency, compact structure design fine looking and good temperature control performance etc; Material outlet temperature from this machine can be self controlled so it is suitable for the hot filling procedure and meanwhile for aseptic cold filling;

Control styles: full-automatic controlled (PLC, touch screen).

|

Model |

LG-UHT-1 |

LG-UHT-2 |

LG-UHT-3 |

LG-UHT-4 |

LG-UHT-5 |

|

Production capacity |

1000 | 2000 | 3000 | 4000 | 5000 |

|

Inlet temperature |

5℃ | 5℃ | 5℃ | 5℃ | 5℃ |

|

Holding time(s) |

4-15 | 4-15 | 4-15 | 4-15 | 4-15 |

|

Sterilize temperature |

105~143℃ | 105~143℃ | 105~143℃ | 105~143℃ | 105~143℃ |

|

Product outlet temperature |

20 | 20 | 20 | 20 | 20 |

|

Ice water inlet temperature |

≤2℃ | ≤2℃ | ≤2℃ | ≤2℃ | ≤2℃ |

|

Steam pressure |

0.5MPa | 0.5MPa | 0.5MPa | 0.5 MPa | 0.5 MPa |

|

Steam consumption |

~150Kg/h | ~210Kg/h | ~280Kg/H | ~350Kg/h | ~420Kg/h |

|

Compressed air pressure |

0.6MPa | 0.6MPa | 0.6MPa | 0.6MPa | 0.6MPa |

|

Compressed air consumption |

50L/H | 50L/H | 60L/H | 60L/H | 70 L/H |

|

External dimension(mm) (homogenizer excluded) |

3500×2000×2500 | 3500×2000×2500 | 4500×2500×2200 | 5000×2000×2200 | 5000×2000×2200 |

|

Total weight of machine |

1700kg | 2000Kg | 2200 Kg | 2500Kg | 2800kg |

Technical Parameter

Production line appilcation:

Description:

Shanghai beyond machinery co., ltd is specialized in supplying various kinds of milk processing line, including the pasteurized milk, UHT milk, flavored milk, yoghurt, cheese and butter, cream, condensed milk etc.

Shanghai Beyond can supply complete turnkey projects for customers, integrating with designing, equipment manufacturing, to installation and commissioning and also training the operators.

UHT milk process: milk transporting tank or vessels, milk filter and collection tank; cooling and storaging tank(milk chilly tank), Mixing/Blending and milk standardization, cream separation, UHT sterilizer(tubular type or plate type) homogenization, degassing, and filling

Features and advantages:

1. Processing capacity can be ranged from 2T/Day to 1000T/Day.

2. High standard design, manufacture and project installation requirements, which guarantee the first-class finish products in the dairy processing line.

3. PLC control the whole production line, saving labor force and facilitate production management.

4. Full-auto CIP cleaning, to ensure whole production line equipments meet food sanitary safety requirements.

5. Whole line with features as high level automatic, low labour intensity, easy operation, safe function and low operation cost.

6. Whole line adopt sanitary design, can be cleaned thoroughly, with high level sanitation.

![]()

Machine list and Technical data for 8000LPH UHT milk plant :

| Flow No. | Name | Model | Main technical parameters | QTY (Units) |

| A | Milk reception unit | |||

| A-1 | Milk pump | 15T/H | SUS304 stainless steel, pump lift is 24 meters, mechanical seal | 2 |

| A-2 | Twin piping filter | 15T/H | Material-touch is SUS304 stainless steel, two pipe, stainless steel filter element 100 mesh | 2 |

| A-3 | Deaerator vessel | 15T/H | SUS 304 stainless steel, tangential feeding,bottom discharge | 2 |

| A-4 | Milk pump | 15T/H | SUS304 stainless steel, pump lift is 24 meters, mechanical seal | 2 |

| A-5 | Electromagnetic flowmeter | 15T/H | SUS 304, 4-20mA Signal output, pulse counting | 2 |

| A-6 | Buffer tank | 5000L | SUS304 stainless steel, PU insulation,conical head, sealed manhole, breathing valve,CIP cleaning ball, digital show thermometer, plate anti vortex, adjustable legs | 2 |

| A-7 | Milk pump | 15T/H | SUS304 stainless steel, pump lift is 24 meters, mechanical seal | 2 |

| A-8 | Milk clarifier | 10000L/H | Disk separator, automatic control, two-phase, started with frequency conversion, self-discharging | 2 |

| A-9 | Plate cooler | 15T/H | SUS304 stainless steel, one section, ΔT=16°C, outlet milk temperature is 4°C | 2 |

| Flowmeter | 15T/H | SUS 304, pointer type | 2 | |

| Subtotal | ||||

| B | Pre-pasteurization & storage unit | |||

| B-1 | Milk storage tank | 20000L | SUS304, 60mmPU insulation, skirt base, and inclined bottom discharging, Miller jacket, closed side manhole ladder, guardrail, digital thermometer,sampling valve, Germany JUMO temperature sensor, rambeau static pressure sensor, CIP cleaning ball, breathing valve, lateral mixing 960rpm | 4 |

| B-2 | Milk pump | 20T/H | SUS304 stainless steel, pump lift is 24 meters, mechanical seal | 1 |

| B-3 | Milk pump | 15T/H | SUS304 stainless steel, pump lift is 24 meters, mechanical seal | 1 |

| B-4 | Plate pasteurizer | 20T/H | Material-touch is SUS304 stainless steel,plate type, 5℃inlet ,85°C, 15s sterilize,4℃ outlet, temperature-automatic control, with temperature recorder, CIP cleaning, Spirax sarco steam depressure and control system | 1 |

| B-5 | High pressure homogenizer | 10T/H | 25MPa, including starting cabinet | 2 |

| Subtotal | ||||

| C | Milk Sterilization & Filling unit | |||

| C-1 | Tubular sterilizer |

10T/H | SUS304 stainless steel, aseptic tye, tubular type, inlet material temperature:20 ℃, sterilizing temperature:137℃, 5S, output temperature 30℃, Simens PLC automatic touch screen control, UK Spirax Sarco steam control system, imported flow meter, frequency converter, temperature sensor, stainless steel electric control cabinet | 1 |

| C-2 | Full-automatic vacuum degasser | 10T/H | Full-automatic control, SUS304 stainless steel, differential pressure transducer imported from Germany Labom, working vacuum degree -0.64~-0.85Kpa, flow control is frequency converted type, working together with sterilizer, with condensing device | 1 |

| C-3 | High pressure homogenizer | 10T/H | 25MPa, including starting cabinet, frequency conversion control | 1 |

| C-4 | pillow filling machine | 500ml/bag,6000bags/hour | 1 | |

| C-5 | pillow filling machine | 1000ml/bag,6000bags/hour | 1 | |

| Subtotal | ||||

| D | Full automatic CIP system | |||

| D | Full-automatic CIP system | 3×3T | Three tanks, double circulation, full-auto CIP, double layer insulation tank, tank material SUS304 stainless steel,acid & alkali tank with stirrer, PLC touch screen control, high & low liquid level alarm system, Spirax Sarco temperature auto control, JUMO temperature sensor, electricity conductivity, flow rate switch, Shanghai YUAN brand progress pump 3 pieces, 20T/H, pumping lift 36M, ABB motor, plate heater on line temperature rising, 300L concentrated acid & alkali tank, tank material is SUS316L , The USA imported pneumatic diaphragm pump two pieces. | 1 |

| R | CIP return pump | 30T/H | SUS316L stainless steel, pump lift 24 meters, mechanical seal, | 4 |

![]()

![]()

![]()