-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Small Conjunct Type 500LPH CIP Cleaning System For Milk Dairy Industry

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | SUS 304/ SUS316 | Control Type | Small Type |

|---|---|---|---|

| Working Circuits | 1 Circuits | Steam Pressure Reducer Valve | Spirax Sarco From UK |

| Tank Size | 1000L-10000L | Sea Port | Shanghai |

| High Light | cip cleaning system food processing,cip tank cleaning |

||

small conjunct type 500LPH CIP cleaning system small type CIP system mini CIP

The system can perform the acid cleaning , alkali cleaning and hot water cleaning separately. And also the system can draw up the special full-auto cleaning program according to the request. It will not only clean all the equipments efficiently, but also limit the growing of the microorganism, meanwhile, we can also deploy the semi-auto and full-auto controlling system according to the customer’s requirements.

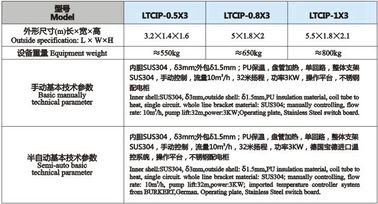

| Specification | LTCIP-0.5X3 | LTCIP-0.8X3 | LTCIP-1X3 |

| Outside specification: (L* W* H) | 3.2*1.4*1.6 | 5*1.8*2 | 5.5*1.8*2.1 |

| Equipment weight | ≈550kg | ≈650kg | ≈800kg |

|

Basic manually technical parameter |

Inner shell:SUS304, δ3mm,outside shell: δ1.5mm,PU insulation material, coil tube to heat, single circuit. whole line bracket material: SUS304; manually controlling, flow rate: 10m³/h, pump lift:32m,power:3KW;Operating platform, Stainless Steel switch board. |

||

| Semi-auto basic technical parameter | Inner shell:SUS304, δ3mm,outside shell: δ1.5mm,PU insulation material, coil tube to heat, single circuit. whole line bracket material: SUS304; manually controlling, flow rate: 10m³/h, pump lift:32m,power:3KW; imported temperature controller system from BURKERT,German. Operating platform, Stainless Steel switch board. | ||

| Minimum Order Quantity: | One set/one line |

| Price: | negotiation |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50 Sets Per Season |

| Delivery Time: | 50-100 working days upon receipt of payment and confirmed the drawings |

| Packaging Details: | PE film wrapping, or carbon steel frame packing, or wooden case packing as to clients’ requirement |

| Warranty | 12 months after commissioning |

|

After sales service |

Engineers available to service machinery overseas |

Description:

Shanghai beyond machinery co., ltd is specialized in supplying various kinds of milk processing line, including the pasteurized milk, UHT milk, flavored milk, yoghurt, cheese and butter, cream, condensed milk etc.

Shanghai Beyond can supply complete turnkey projects for customers, integrating with designing, equipment manufacturing, to installation and commissioning and also training the operators.

UHT milk process: milk transporting tank or vessels, milk filter and collection tank; cooling and storaging tank(milk chilly tank), Mixing/Blending and milk standardization, cream separation, UHT sterilizer(tubular type or plate type) homogenization, degassing, and filling

Features and advantages:

1. Processing capacity can be ranged from 2T/Day to 1000T/Day.

2. High standard design, manufacture and project installation requirements, which guarantee the first-class finish products in the dairy processing line.

3. PLC control the whole production line, saving labor force and facilitate production management.

4. Full-auto CIP cleaning, to ensure whole production line equipments meet food sanitary safety requirements.

5. Whole line with features as high level automatic, low labour intensity, easy operation, safe function and low operation cost.

6. Whole line adopt sanitary design, can be cleaned thoroughly, with high level sanitation.

![]()

![]()

![]()

![]()