-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

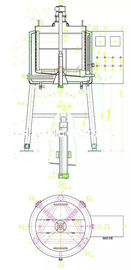

Stainless Steel Mixing Chocolate Melting Tank With Electrical Control Box

| Voltage | 220V/380V | Power(W) | 2-5KW |

|---|---|---|---|

| Weight | 100-500KG | Dimension(L*W*H) | 600*400*800mm |

| Warranty | 1 Year | After-sales Service | Online Support |

| Application | Chocolalte | Material | Stainless Steel 304/316L |

| Usage | Mixing And Melting | ||

| Highlight | dairy processing equipment,milk processing plant |

||

75L-2000L Chocolate Melting and Storage Tank

chocolate storage tank :

1. Made of SUS304 stainless steel;

2. With PU as insulation;

3. Heated by hot water in jacket;

4. Temperature is fully automaticly controlled;

5. Volume: 75L-150L-2000L etc(according to customer requirements);

6. Can be used to melt chocolate;

7. With scraper on the agitator where contact with the inner shell,

the scraper can prevent the chocolate being sticked on the inner shell;

8. The top cover is removable, which make it easy to load the product;

9. With electrical control box to control the temperature and keep it at a certain degree.

Technical data of Chocolate heat preservation tank

| Model | Max Volume (L) | Power(KW) | Weight(kg) | Dimension(mm) |

| BYQKLG 5000 | 5000 | 7.5 | 3000 | Φ2000*2710 |

| BYQKLG 3000 | 3000 | 5.5 | 2000 | Φ1700*2500 |

| BYQKLG 2000 | 2000 | 3 | 1500 | Φ1400*2500 |

| BYQKLG 1000 | 1000 | 2.2 | 1000 | Φ1220*1850 |

| BYQKLG 500 | 500 | 1.5 | 600 | Φ1000*1380 |

| BYQKLG 300 | 300 | 1.5 | 200 | Φ900*1250 |

| BYQKLG 200 | 200 | 1.1 | 180 | Φ800*1250 |

| BYQKLG 100 | 100 | 1.1 | 150 | Φ700*1250 |

![]()

![]()

Strengthen food safety

Since the system is completely sealed to maintain product hygiene, there is no risk of contamination entering the system. In fact, the entire mixer is designed for sanitary execution.

Degassing also extends the shelf life of the final product because it makes the environment unsuitable for microorganisms.