-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

220V / 380V 1000LPH Milk Pasteurization Machine 6KW With High Performance

| Place of Origin | Shanghai,China |

|---|---|

| Brand Name | Beyond |

| Certification | ISO9001:2015 |

| Model Number | 500LPH-20TPH |

| Minimum Order Quantity | 1 piece |

| Packaging Details | Container Lading;Wooden Package and Frameworks;PE Film Wraps |

| Delivery Time | 30 days after payment |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 sets per year |

| Control Type | Full-auto/Semi-auto | Condition | New |

|---|---|---|---|

| Warranty | 1 Year | After-sales Service | Field Installation, Commissioning And Training |

| Voltage | 220V/380V/415V | Weight | 1080KG |

| Dimension(L*W*H) | 2000*2000*2200mm | Power(W) | 6KW |

| Application | Milk/Fruit Juice/Yogurt/Tea Beverage | Capacity | 500LPH-20TPH |

| Material | SUS304/SUS316L | ||

| Highlight | dairy processing equipment,milk processing plant |

||

Full-Automatic Plate HTST Pasteurizer (4 sections)

Application Scope

Full automatic Plate HTST pasteurizer for Milk, soybean milk, Grape wine;flavoredd milk, or milk beverage etc.

Standard configuration:

A. plate heat exchanger;

B. material-balance drum;

C. hot water-balance drum;

D. pump of hot water charging;

E. pump of material transferring;

F. hot water making machine;

G. electricity box;

H. valves and pipes of stainless steel etc.

Usage:

This machine stands between the pasteurizer and the UHT, can be used for PET hot filling or roof shape filling sterilize.

Structure:

Semiautomatic control: UK Spirax Sarco steam pressure reduce valve, German Burkert or Spirax Sarco temperature control system, German Labom temperature transducer, Anthone temperature recorder without paper, South hot water pump, Siemens LOGO control, the precision of temperature control is ±0.5 degree.

Full automatic control: UK Spirax Sarco steam pressure reduce valve, German Burkert or Spirax Sarco temperature control system, German Labom temperature transducer, Anthone temperature recorder without paper, South hot water pump, Siemens PLC full automatic control with touch screen, the precision of temperature control is ±0.5 degree.

Technical parameters:

5°C→65°C (homogenization)→120°C(15s)→25°C5°C

Control elements list:

|

Semi-automatic control configuration |

Item |

Brand or supplier |

|

Controller |

Siemens LOGO |

|

|

Reducer valve |

Spirax Sarco from UK |

|

|

Temperature control system |

Burkert or Spirax Sarco |

|

|

Temperature transducer |

Labom from Germany |

|

|

Temperature recorder without paper |

Anthone |

|

|

Pipes and valves |

Shanghai Yuanan |

|

|

Hot water pump |

From Italy |

|

|

Precision of temperature control is ±0.5 degree |

||

|

Full automatic control configuration |

Item |

Brand or supplier |

|

Controller |

Siemens Touch-screen PLC |

|

|

Reducer valve |

Spirax Sarco from UK |

|

|

Temperature control system |

Burkert or Spirax Sarco |

|

|

Temperature transducer |

Labom from Germany |

|

|

Pipes and valves |

Shanghai Yuanan |

|

|

Hot water pump |

From Italy |

|

|

Precision of temperature control is ±0.5 degree |

||

Parameter:

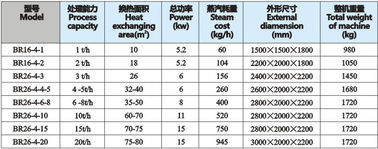

|

Model |

Capacity |

Heat exchange area(m²) |

Power (kw) |

Steam consumption (kg/h) |

Dimension (L×W×H)mm |

Machine weight (kg) |

|

BR16-UB-1 |

1T/H |

10 |

5.2 |

120 |

1500×1500×1800 |

980 |

|

BR16-UB-2 |

2T/H |

18 |

5.2 |

210 |

2200×2000×1800 |

1050 |

|

BR26-UB-3 |

3T/H |

26 |

6 |

280 |

2400×2000×2200 |

1450 |

|

BR26-UB-4-5 |

4 -5T/H |

32-40 |

6 |

340 |

2600×2000×2200 |

1680 |

|

BR26-UB-6-8 |

6 -8T/H |

35-50 |

8 |

400 |

2800×2000×2200 |

1720 |

|

BR26-UB-10 |

10T/H |

60-70 |

11 |

450 |

2800×2000×2200 |

1720 |

|

BR26-UB-15 |

15T/H |

70-75 |

15 |

550 |

2800×2000×2200 |

1720 |

|

BR26-UB-20 |

20T/H |

75-80 |

15 |

620 |

3000×2000×2200 |

1720 |