-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

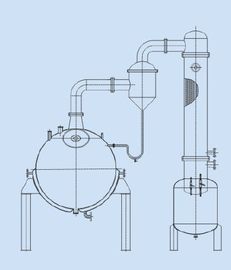

200kg/H Dairy Processing Plant Sphere Concentrating Tank For Pharmacy / Juice

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | SUS304/316L Both Available | Production Standard | GMP Conformity |

|---|---|---|---|

| Condensing Rate | 1.35-1.45 | Condition | New |

| Certification | ISO9001 | ||

| Highlight | dairy processing equipment,milk processing plant |

||

Equipment name:Sphere Concentrating Tank for Pharmacy/Juice/Candy

• Scope of application:

The equipment is applied for the solution function such as vacuum concentration,crystallization,paste collection,distillation,alcohol recycling etc;in the industries such as Chinese medicine,western medicine,foodstuff,dextrose,juice,candy,pharmaceutical,chemical industry and so on.The condensing rate could reach 1.35~1.45.

• Equipment description:

The machinery is composed of four important parts including main body of condensing boiler,gas liquid separator,cooler and water tank.All material are supported by SUS304 to make sure meeting GMP standards during the production.Beause of decompression condense mode applied in the equipment so the condensing time is shortened and the available compositions of thermal zensitive materials also shall not be damaged

• Technical parameters:

| Specification | QN-250 | QN-500 | QN-700 | QN-1000 | QN-1500 | QN-2000 |

| Evaporation Capacity(kg/h) | 80 | 110 | 150 | 200 | 280 | 410 |

| Nominal Capacity (L) | 250 | 500 | 700 | 1000 | 1500 | 2000 |

| Interlayer Pressure (Mpa) | ||||||

| Vacuum degree (Mpa) | ||||||

| Heating Area (m2) | 1.0 | 1.5 | 2.7 | 3.1 | 4.0 | 5.0 |

| Condensate Area(m2) | 3.0 | 4.0 | 5.0 | 8.0 | 12.5 | 18.0 |

| Weight of equipment (kg) | 415 | 625 | 760 | 950 | 1700 | 1900 |

| External dimension (mm) | 1000*1000*2300 | 2100*1200*2500 | 2200*1400*2500 | 2000*1500*2700 | 3000*1600*4600 | 3600*1900*4000 |