-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

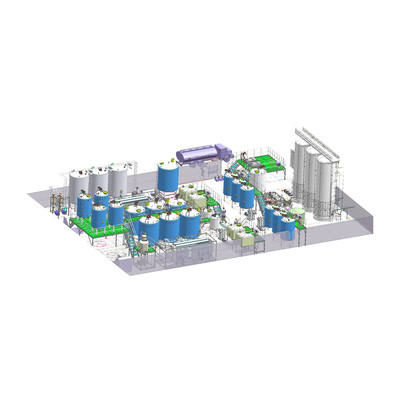

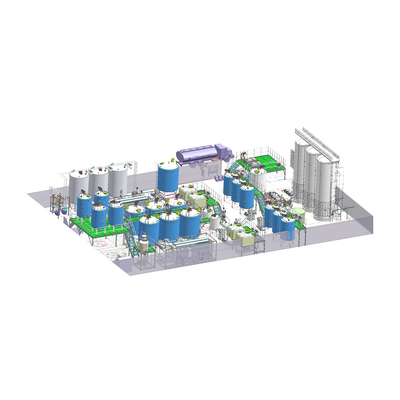

SUS316 Fresh Milk Processing Equipment Dairy Beverage Processing Line

| Main Material For Machines | SUS304 Or SUS316 | Advantage | Easy To Operate |

|---|---|---|---|

| Fresh Milk Inlet Temperature | 4 ℃ Or 30℃ | Filling Temperature | 20~30 ℃ |

| Shelf Life | 35-40days, 3months, 6months, 12months (keep At Room Temperature ) | ||

| Highlight | Fresh Milk Beverage Processing Line,SUS316 Beverage Processing Line,SUS316 dairy processing machine |

||

Fresh Milk Processing Equipment/Dairy and Beverage Processing Line

![]()

Description:

Automatic production line

Provide installation and commissioning services

Capacity from 500 litres to 20000 litres per hour

Bottles, sachets (bags), cartons and cups are packaged for customers to choose from.

Because the product can be stored for a long time without deterioration and does not need refrigeration, it has many advantages for manufacturers, retailers and consumers. This includes expensive products such as cream, desserts and sauces.

Equipment introduction:

The production line is used to produce pasteurized milk, yogurt, lactic acid bacteria beverage and milk beverage. Complete production line, including milk collection system / power reduction system, water treatment system, sugar melting and mixing system, filtration, degassing, homogenization and sterilization, heat preservation, fermentation, CIP cleaning, filling, coding and packaging.

Optional configuration

Raw materials: milk / goat milk / yak milk / milk powder

![]()

Features and advantages:

1. Processing capacity can be ranged from 2T/Day to 1000T/Day.

2. High standard design, manufacture and project installation requirements, which guarantee the first-class finish products in the dairy processing line.

3. PLC control the whole production line, saving labor force and facilitate production management.

Specifications:

| Brand Name: | Shanghai Beyond |

| Model Number: | BY-FM |

| Capacity | 5-300TPD |

| Raw material |

Fresh cow milk, buffalo milk, goat milk, camel milk or milk powder, or both mixed |

| End product | Strawberry milk, banana milk, apple flavor milk, chocolate milk, grape milk, mango milk |

| Shelf life |

35-40days, 3months, 6months, 12months (keep at room temperature ) |

| Fresh milk inlet temperature | 4 ℃ or 30℃ |

| Filling temperature | 20~30 ℃ |

| Package for end product | PET bottle, plastic container, etc |

| Certification: | ISO9001/CE/SGS |

| Main material for machines | SUS304 or SUS316 |

| Place of Origin: | China |

| Manufacturer history | More than 10years |

| Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

| Power consumption(Kw) | energy saving type, about 100-500kw, |

| Operator needed | About 6-20persons |

| Cooling water consumption | About 80-300M3 |

| Steam consumption | About 300-5000T/H, |

| Factory space needed | About 500-5000Sqm |

| Warranty | 12 months after commissioning |

| After sales service | Engineers available to service machinery overseas |

After the required infrastructure is available on site, our technical team will assemble, install and set up a complete processing line. It is best to work with local technicians. The processing line will always be commissioned after testing by our dairy operator. After the test is successful, the processing line will be debugged. Upon request, our dairy processing operators can stay on site for a period of time to provide additional training.

![]()

![]()

![]()

![]()

Q: I want to enter the dairy processing industry. What should I do?

Please fill in the quotation application form.

Q: can you help us formulate the requirements for equipment and buildings?

Please fill in the quotation application form.

Q: how big is the factory / building?

A: it depends on your requirements and the details you provide in the quotation application form.

Q: can the equipment be installed in the existing building?

A: Yes. We designed the equipment to meet the requirements.

Q: what infrastructure is needed?

You need water, electricity and sewage treatment systems. Your answers in the RFQ will help us provide you with relevant details.

Q: how many employees are needed?

Please fill in the quotation application form. It depends on capacity and product.

Q: what level of education should employees have?

A: employees should have knowledge of dairy processing.

Q: what kind of training do you need?

A: technical training requires training in hygiene and processing technology.

Q: can scherjon help us with the training?

A: Yes. We provide training during installation and in the Netherlands on request.

Q: do you have a cheese manufacturer to start a factory?

A: Yes. We have international cheese manufacturers.

Q: do you sell independent machines?

A: Yes. Please visit our website and ask for a quotation.