-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Plastic Pouch / Bottle Package Liquid Dairy Processing Plant 200ml 500ml 1000ml

| Place of Origin | CHINA |

|---|---|

| Brand Name | BEYOND |

| Certification | ISO 9001/SGS/CE/TUV |

| Model Number | BY-PM |

| Minimum Order Quantity | 1SET |

| Price | negotiable |

| Packaging Details | export standard packing, worthy for long distance sea shipping |

| Delivery Time | 60-80days upon the recipt of downpayment and confirmation of drawings |

| Payment Terms | T/T, L/C, west union |

| Supply Ability | 20 sets per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Processing Line | Liquid Milk Processing | Capacity | 5000-100000L Per Day |

|---|---|---|---|

| End Product | Pasteurized Milk | Power Supply | 380V 50Hz |

| Highlight | milk processing equipment,dairy processing equipment |

||

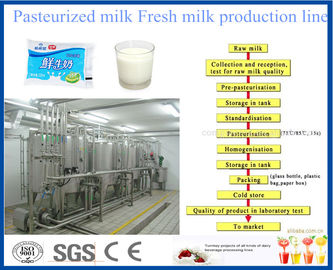

200-1000ml plastic pouch or bottle package Pasteurized Milk Processing Line 12months warranty

Company introduction:

Shanghai Beyond Machinery Co., Ltd, established in the year of 2005, is a manufacture specialized technology-oriented machinery. BEYOND is able to provide the turn-key projects, including the design, manufacture, installation and commissioning for the production lines of liquid food such as dairy, drink, ice cream, fruit and vegetable, bio-engineering, chemical and pharmaceutical.

Cooperated with several domestic and abroad Light Industrial or scientific research institutions, we absorb their advanced technology and then take base to develop new even better process techniques, we are now specializing in all kind of sanitary stainless steel tanks, heater, cooler, sterilizer, concentrator, pump and other pipe and fittings.

Through the years of the common efforts of our staff, we have obtained high share in the market of machinery industry, and have developed ourselves into a medium-sized enterprise of certain popularity in the industry. Combining scientific research, technical development, production, marketing and after-sale service, we keep ourselves acting strictly in accordance with the quality assurance system of ISO 9001, to ensure us to provide the good quality equipments that are in accordance with the relative standards of Juice, Dairy, Pharmacy, bio-chemical, such as HACCP, QS and GMP etc.

Thank you very much for the trust of all our customers and we expect to build up good business cooperation friendship with more and more clients, and warmly welcome to your visiting to our factory!

Part 1. Basic technical parameters of this project

1. Product Variety: 5000L/H dairy production line.

2. Raw material: fresh milk(50%) and milk powder(50%)

3. Filling type: plastic pouch,1000ml/pouch;

Production line flow chart design:

![]()

Equipment list and quantity

| No. | Flow No. | Name | Model | Unit | QTY |

| 1 | A | Milk reception unit | |||

| 2 | A-1 | weighbridge | PCS | 1 | |

| 3 | A-2 | Electronic scale | PCS | 1 | |

| 4 | A-3 | Milk weighing tank | 500L | PCS | 2 |

| 5 | A-4 | Milk reception tank | 1000L | PCS | 1 |

| 6 | A-5 | Milk pump | 10T/H | PCS | 2 |

| 7 | A-6 | Twin piping filter | 10T/H | PCS | 1 |

| 8 | A-7 | Plate cooler | 10T/H | PCS | 1 |

| 9 | A-8 | Blending tank | 10000L | PCS | 2 |

| 10 | A-9 | Milk pump | 10T/H | PCS | 1 |

| 11 | Subtotal | ||||

| 12 | B | Blending unit | |||

| 13 | B-1 | Blending tank | 5000L | PCS | 3 |

| 14 | B-2 | Milk pump | 10T/H | PCS | 1 |

| 15 | B-3 | Milk pump | 10T/H | PCS | 1 |

| 16 | B-4 | plate heat exchanger | 10T/H | PCS | 1 |

| 17 | B-5 | powder-water mixer | 10T/H | PCS | 1 |

| 18 | B-6 | Twin piping filter | 10T/H | PCS | 1 |

| 19 | Subtotal | ||||

| 20 | C | UHT sterilize and filling unit | |||

| 21 | C-1 | Tubular UHT | 6T/H | PCS | 1 |

| 22 | C-2 | Degasser | 6T/H | PCS | 1 |

| 23 | C-3 | High pressure homogenizer | 6T/H | PCS | 1 |

| 24 | C-4 | Aseptic brick filling machine | 6000pack/hour | PCS | 1 |

| 25 | Subtotal | ||||

| 26 | D | Water Treatment system | |||

| 27 | D | Water Treatment system | 5T/H | PCS | 1 |

| 28 | Subtotal | ||||

| 29 | E | Semi automatic CIP system | |||

| 30 | E | Semi-automatic CIP system | 4×3T | PCS | 1 |

| 31 | R | CIP return pump | 20T/H | PCS | 3 |

| 32 | Subtotal | ||||

| 33 | Total price for equipment | ||||

| 34 | F | Installation unit | |||

| 35 | F-1 | product piping system | PCS | 1 | |

| 36 | F-2 | power piping system | PCS | 1 | |

| 37 | F-3 | electrical distribution cabinets | PCS | 1 | |

| 38 | F-4 | electric installation material | PCS | 1 | |

| 39 | F-5 | installation and commissioning cost | PCS | 1 | |

Commercial terms

*Terms of Payment: 40% TT as down payment, the balance before loading,

or 100%L/C at sight against shipping documents ;

*Delivery time:

120 days after receive TT deposit or formal 100% L/C, upon approval on technical drawings and specifications by client.

*Duration of Guarantee:

1. within 12 months since the installation and commissioning of equipment are finished, If the defects of equipment and spare parts result from the seller, the seller will supply spare parts and maintenance by free of charge. If the defects result from the buyer’s improper use of equipment, seller will charge the cost of maintenance and spare parts.

2. After 12 months since the installation finished, if the equipment and spare parts are defected, the seller will charge the cost of maintenance and spare parts.

3. If Buyer request Seller and engineer to Buyer's factory, buyer should supply seller’s workers the round trip air tickets and subsidary for each worker per day. And the local traffic, accommodation and lodging fees should also be available.

*Installation terms:

1. 50-60 days for installation and commissioning.

2. BEYOND CO., provide installation, commissioning of all equipment supplied by BEYOND CO., as stated in the quotations.

![]()

![]()

![]()