-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Aseptic Procedure Milk Pasteurization Equipment For Milk Processing Plant

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Aseptic Tube-in-tube Sterilizer | Material | SUS304 Or SUS316 |

|---|---|---|---|

| Control | Automatically Control | Advantage | Strong Safety |

| Highlight | milk sterilizer machine,dairy pasteurization equipment |

||

Aseptic Tube-in-tube Sterilizer Milk Pasteurization Equipment Used to Perform Continuous Sterilization

This machine is used to perform continuous sterilization on much thicker products, such as various of concentrated juice,paste and similar high viscidity products.

Procedures technical: 25℃→95-121℃(120S-180S)→25℃-35℃, the final products can be filled in aseptic big bags for room temperature storage;

Compared to the other model, this machine has the following characteristics:

- temperature difference between the product and the heating medium is small, so the heating is gentle; the heating tubular adopts tube in tubes type and the surface of the tube is mirror polished to reduce the deposition on the surface which will longer the working life of the machine.

- it is of high degree automatic, can automatically control the CIP cleaning, self sterilizing, and the whole procedures steps; all the procedures are recorded and controllable.

- it is of precise and reliable sterilizing temperature control; all the affecting factors such as steam pressure, steam flow rate, product flow rate are all controllable;

- the inside of the tubular adopts advanced polish procedure, all tubes can perform fully cleaning, self sterilizing ensures the system at aseptic state;

- the system is strong safety, the fittings all adopts reliable materials.

- the system is of high reliable, main parts such as product pump, hot water pump, all kinds of valves, elements of the electrics are all of world known brands.

- with self SIP system.

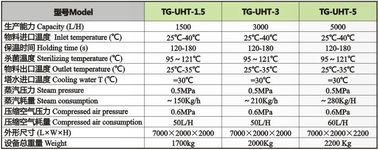

| Model | TG-UHT-1.5 | TG-UHT-3 | TG-UHT-5 |

| capacity(L/H) | 1500 | 3000 | 5000 |

| Product inlet temperature(℃) | 25℃-40℃ | 25℃-40℃ | 25℃-40℃ |

| Warm keeping time(S) | 120-180 | 120-180 | 120-180 |

| Sterilization temperature(℃) | 95~121℃ | 95~121℃ | 95~121℃ |

| Product outlet temperature(℃) | 25℃-35℃ | 25℃-35℃ | 25℃-35℃ |

| Cooling water inlet(℃) | ≤30℃ | ≤30℃ | ≤30℃ |

| Steam pressure | 0.5MPa | 0.5MPa | 0.5MPa |

| steam consumption | ~150Kg/h | ~210Kg/h | ~280Kg/H |

| Compressed air pressure | 0.6MPa | 0.6MPa | 0.6MPa |

| Compressed air consumption | 50L/H | 50L/H | 60L/H |

| External dimension | 7000×2000×2000 | 7000×2000×2000 | 7000×2000×2200 |

| Total weight | 1700kg | 2000Kg | 2200 Kg |

Full automatic control: Spirax sarco reducer valve from UK, German Burkert & Spirax sarco temperature control system, German Labom temperature transducer, yuanan pipes and valves from shanghai , hot water pump from Italy, siemens LOGO touch-screen and PLC full automatic control, the precision of temperature control is ±0.5 degree, with self CIP and SIP system

Aseptic plate type UHT sterilizer(5 sections)

This UHT system adopts ultra high heat treatment to sterilize the liquid dairy products, tea drink or juice for the the aseptic filling production; the sterilize temperature is 137℃ holding for 3~5S, to remain the nature nutrition and flavor of the milk and juice;

This machine has the following characteristics: high heat reuse efficiency, compact structure design fine looking and good temperature control performance etc; Material outlet temperature from this machine can be self controlled so it is suitable for the hot filling procedure and meanwhile for aseptic cold filling;

Control styles: full-automatic controlled (PLC, touch screen).

![]()

| | | | | |

| 1000 | 2000 | 3000 | 4000 | 5000 |

| 5℃ | 5℃ | 5℃ | 5℃ | 5℃ |

| 4-15 | 4-15 | 4-15 | 4-15 | 4-15 |

| 105~143℃ | 105~143℃ | 105~143℃ | 105~143℃ | 105~143℃ |

| 20 | 20 | 20 | 20 | 20 |

| ≤2℃ | ≤2℃ | ≤2℃ | ≤2℃ | ≤2℃ |

| 0.5MPa | 0.5MPa | 0.5MPa | 0.5 MPa | 0.5 MPa |

| ~150Kg/h | ~210Kg/h | ~280Kg/H | ~350Kg/h | ~420Kg/h |

| 0.6MPa | 0.6MPa | 0.6MPa | 0.6MPa | 0.6MPa |

| 50L/H | 50L/H | 60L/H | 60L/H | 70 L/H |

| 3500×2000×2500 | 3500×2000×2500 | 4500×2500×2200 | 5000×2000×2200 | 5000×2000×2200 |

| 1700kg | 2000Kg | 2200 Kg | 2500Kg | 2800kg |