-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

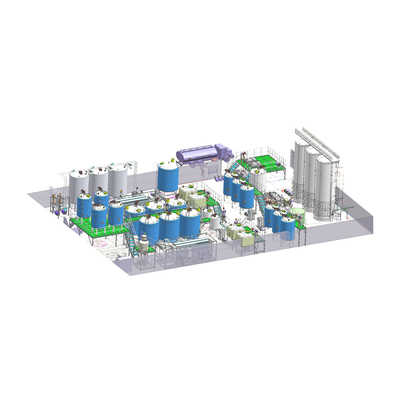

5000LPH PLC Control Dairy Processing Plant , Milk Powder / Fresh Milk Processing Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Voltage | 380V 50Hz/110V 60hz/415V 50Hz | Cooling Water Consumption | About 80-300M3 |

|---|---|---|---|

| Factory Space Needed | About 500-5000Sqm | Raw Material | Fresh Cow Milk, Buffalo Milk, Goat Milk, Camel Milk Or Milk Powder, Or Both Mixed |

| End Product | Fresh Milk, Pasteurized Milk, Standardized Pasteurized Milk | ||

| Highlight | dairy processing equipment,milk processing plant |

||

![]()

5000LPH Dairy Processing Equipment from Milk Powder or Fresh Milk with 500ml pouch packing

Specifications:

| Brand Name: | Shanghai Beyond |

| Model Number: | BY-NNX |

| Capacity | 5-300TPD |

| Raw material |

Fresh cow milk, buffalo milk, goat milk, camel milk or milk powder, or both mixed |

| End product |

Fresh milk, pasteurized milk, standardized pasteurized milk |

| Shelf life | 5-7days (keep at 4 ℃ ) |

| Final product fat (%) |

Semi-skimmed or double toned milk (1.5%); Full cream(3% or 6%); Toned milk(3%) |

| SNF | 8.5%(min) |

| Fresh milk inlet temperature | 0~4 ℃ |

| Filling temperature | 4 ℃ |

| Package for end product | Glass bottle/PP or PE bottle, Roof type carton box |

| Certification: | ISO9001/CE/SGS |

| Main material for machines | SUS304 or SUS316 |

| Place of Origin: | China |

| Manufacturer history | More than 10years |

| Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

![]()

Features and advantages:

1. Processing capacity can be ranged from 2T/Day to 1000T/Day.

2. High standard design, manufacture and project installation requirements, which guarantee the first-class finish products in the dairy processing line.

3. PLC control the whole production line, saving labor force and facilitate production management.

4. Full-auto CIP cleaning, to ensure whole production line equipments meet food sanitary safety requirements.

Description:

Shanghai Beyond Machinery Co., Ltd. is a professional machinery manufacturer based on technical developing. Combining with R&D, manufacturing, installation debugging and training, we are engaged in producing the liquid projects used in Dairy,Fruit &Vegetable juice,Beverage,Tea,Brewing,Flavoring,Pharmacy,Egg,Bone & Meat processing and Daily chemical products etc.

. We have cooperated with the same occupations from domestic and international to introduce and develop many advanced procedures of manufacturing and designing.

With so many excellent staffs in technical and marketing, we are distributing in a more flexible and invigorative working surroundingdevelopment and helping our customers more success in the corresponding areas by offering better products and service.

We supply all kinds of dairy processing line, for turnkey projects, include designing, equipment manufacturing, installation, commissioning and training workers etc.

| NO. | FLOW NO. | NAME | SIZE | MAIN TECHNOLOGY PARAMETER | UNIT | QTY |

| 1 | A | MILK RECEIVE AND STORAGE UNIT | ||||

| 2 | A-1 | Milk pump | Q=10T/h | SUS304 stainless steel,pump lift 24M,mechanical seal | pcs | 1 |

| 3 | A-2 | Electronic scale | maximum weighing 1000KG | pcs | 1 | |

| 4 | A-3 | Milk weighing tank | V=300L | made of SUS304 stainless steal,single layer,product feeded in through 40 mesh filter net,CIP cleaning ball | pcs | 1 |

| 5 | A-4 | Milk receiving tank | V=500L | SUS304 stainless steel,single layer,CIP cleaning ball | pcs | 1 |

| 6 | A-5 | Milk pump | Q=10T/h | SUS304 stainless steel, pump lift 24M, mechanical seal | pcs | 1 |

| 7 | A-6 | Twin piping filter | Q=10T/h | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh | pcs | 1 |

| 8 | A-7 | Plate cooler | Q=10T/h | SUS304 stainless steel,one stage,ice water cooling,20-4℃ | pcs | 1 |

| 9 | A-8 | Milk storage tank | 5000L | SUS304 stainless steel,heat insulated,dimple jacket,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet | pcs | 2 |

| 10 | A-9 | Milk pump | Q=3T/h | SUS304 stainless steel, pump lift 24M,mechanical seal | pcs | 1 |

| 11 | Subtotal A: | |||||

| 12 | B | HOMOGENIZER/PASTEURIZE UNIT | ||||

| 13 | B-1 | Plate type pasteurizer | 2T/h | SUS304 stainless steel, plate type, inlet temperature 4℃, pasteurizing temperature 85℃, holding tube 15S for milk ,outlet temperature 4℃, PID temperature auto control,include Spirax Sarco steam control system,milk balance tank, milk pump, plate heat exchanger, pipes and valves, frame and support, electrical control box etc | pcs | 1 |

| 14 | B-2 | High pressure homogenizer | 2T/h | 25MPa,(starting box included) | pcs | 1 |

| 15 | Subtotal B | |||||

| 16 | C | FILLING UNIT | ||||

| 17 | C-1 | High position tank | V=1000L | SUS304 stainless steel,heat insulated,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet | pcs | 2 |

| 18 | C-2 | Plastic bag filling machine | 6000 b/h,500ml/bag | pcs | 2 | |

| 19 | C-3 | High level platform | SUS304,4500*3000*2000mm | pcs | 1 | |

| 20 | Subtotal C: | |||||

| 21 | D | CIP UNIT | ||||

| 22 | D | CIP system | 3*1000L | Three tanks, single circulation, Semi-auto CIP, double layers insulation tank, tank material SUS304 stainless steel,acid&alkali tank with stirrer, high&Low liquid level alarm system, Spirax Sarco temperature auto control, JUMO temperature sensor, Shanghai YUAN brand progress pump 1 pieces, 10T/H, pumping lift 36M,100L concentrated acid & alkali tank which material is SUS316L , The USA imported pneumatic diaphragm pump two pieces. | pcs | 1 |

| 23 | R-1 | Return pump | Q=20T/h | SUS316L stainless steel,pump lift 24M,Mechanical Seal | pcs | 4 |

| 33 | F | INSTALLATON UNIT | ||||

| 34 | F-1 | Stainless piping system | including CIP systemand all product pipe line ,SMS standard,¢63,¢51,¢38 | set | 1 | |

| 35 | F-2 | Power piping system | power pipe line ,without heat insulation | set | 1 | |

| 36 | F-3 | electric controlling box | control box of all equipments,customer connect the electic cable to the electric controlling box of Beyond company | set | 1 | |

| 37 | F-4 | electric installation material | electric installation material of all equipments | set | 1 | |

*installation terms:

1. 50-60 days for installation and commissioning.

2. BEYOND CO., provide installation, commissioning of all equipment supplied by BEYOND CO., as stated in the quotations.

3. buyer provide round way air tickets,local traffic , room and board,in addition pay subsidary per day for each engineer.

![]()

![]()

![]()