-

Dairy Processing Plant

-

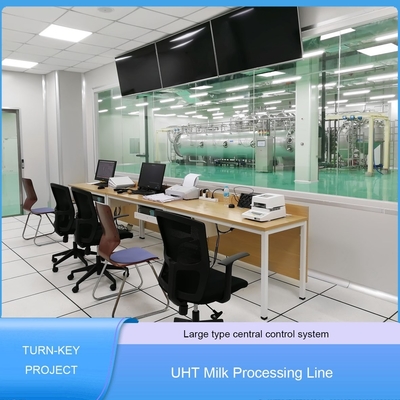

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Uht Processed Milk Dairy Plant Equipment For Pasteurization Process Of Milk

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | UHT Milk Processing Line | Material | SUS304 Or SUS316 |

|---|---|---|---|

| Function | Used For Milk | Operation | Full-auto Or Semi-auto |

| Shelf Life | 6 Months | ||

| Highlight | milk processing unit,milk production equipment |

||

UHT milk processing equipment long shelf life milk equipment high temperature sterilizing milk

![]()

Plate sterilizer (UHT)

Technicals: 5℃→65℃(homogenizer)→137℃(3-5S)→20℃-25℃. This UHT system adopts ultra high heat treatment to sterilize the liquid dairy products, tea drink and juice for the the aseptic filling production; the sterilize temperature is 137℃ holding for 3~5S,by this procedure to remain the nature nutrition and flavor of the milk and juice;

This machine has the following characteristics: high heat reuse efficiency, tight structure design fine looking and temperature control well etc; discharge temperature of this machine can be self controlled so it is available for the hot filling procedure and meanwhile for aseptic cold filling;

Control styles:

full-automatic controlled

(PLC, touch screen).

![]()

| Series | Name. | Size | Specification | Qty | Unit |

| A. soybean milk making unit | |||||

| A-1 | electric pound scale | maximum weighing 250kg | 1 | PCS | |

| A-2 | steam and water mixer | Q=10T/h | made of SUS304 stainless steel,mix the steam and water | 1 | PCS |

| A-3 | heat dip tank | V=1000L | made of sus304 stainless steel, square shape, with filter at bottom, easy to change the water inside, easy to discharge via large diameter outlet | 4 | PCS |

| A-4 | drooling channel | made of sus304 stainless steel,size is 200*200mm | 1 | SET | |

| A-5 | impurity clearing drpooling channel | made of sus304 stainless steel,200*200mm | 1 | SET | |

| A-6 | vibration boult | Q=200Kg/h | the capacity says to dry soyabean,the machine is made of sus304 stainless steel, with shower device | 1 | PCS |

| A-7 | milk and residue seprator(grinder) | Q=150Kg/h | (based on dry bean), diameter Φ200, 90mesh filter mesh | 2 | PCS |

| A-8 | mixture of milk and residue barrel (with agitator) |

V=200L | made of sus304 stainless steel,it is 200L square tank,with vertical agitator | 3 | PCS |

| A-9 | mixture dreg with soy milk pump | Q=3T/h | made of sus304 stainless steel, pump head is 24m,carbide tipped mechanical seal, the inner shell is mirror polished | 4 | PCS |

| A-10 | centrifuge separator | Q=300Kg/h | SUS304,90 mesh filter screen,(measured by dry soybean weight ) | 2 | PCS |

| A-11 | Screw dregs discharge machine | Q=150Kg/h | (measured by dry residue weight ), SUS304 stainless steel | 1 | PCS |

| A-12 | soybean milk Collecting sink | V=200L | made of sus304 stainless steel,square shape, | 1 | PCS |

| A-13 | fresh soy milk tank | V=600L | made of sus304 stainless steel,square shape, with CIP cleaning ball | 1 | PCS |

| A-14 | centrifugal pump | Q=3T/h | made of sus304 stainless steel, pump head is 24m,carbide tipped mechanical seal, the inner shell is mirror polished | 3 | PCS |

| A-15 | continous cooking machine for soy milk | Q=1.5T/h | made of sus304 stainless steel,have 3 tanks for continous cooking | 1 | PCS |

| A-16 | vibration round boult | Q=2T/h | made of sus304 stainless steel,equiped with vibration motor,and 100 mesh filter net | 1 | PCS |

| A-17 | buffering tank | V=2000L | made of sus304 stainless steel,single layer,with off-set vertical agitator,conical cover and bottom, airtight manhole,air vent,digital show thermometer,CIP cleaning ball,glass level meter,anti bow wave plate,with adjustable feet | 1 | PCS |

| A-18 | support table for diping the soybean | frame and support is made of carbon steel,on the top surface is of sus304 stainless stell,water drainage by centralized | 1 | SET | |

| B. hot water preparing unit | |||||

| B-1 | hot water tank | 5000L | made of sus304 stainless steel,double layer with PU as heat insulation, thickness of PU is 60mm,inner shell is of sus304 ,thickness is 3mm,and outer shell is also made of sus304 stainless steel,the thickness of it is 1.5mm,with glass level measure(have exact scale) at the position of 135 degree,CIP cleaning ball, manhole at 45 degree,digital show termometer, diameter of inlet/outlet is φ51 | 1 | PCS |

| B-2 | hot water pump | 10T/H | made of sus304 stainless steel,carbide tipped mechanical seal,inlet/outlet is φ51,pump head is 36m | 1 | PCS |

| B-3 | plate heater | 10T/H | the plate is made of sus304 stainless steel,inlet/outlet is φ51,A3 frame coated by sus304 stainless steel sheet,heat by steam,△T1=60℃ | 1 | PCS |

| B-4 | temperature auto control system | UK Spirax Sarco temperature reducing system, Germen Burkert regulating valves,the temperature is auto controled | 1 | SET | |

| C. blending and preparing unit | |||||

| C-1 | high speed emulsification tank | 500L | square shape,PU insulation is 60mm thick, inner shell is 3mm sus304 stainless steel,outer shell is 1.5mm thick sus304 stainless steel, | 1 | PCS |

| C-2 | centrifugal pump | 5T/H | made of sus304 stainless steel, pump head is 30m,carbide tipped mechanical seal | 1 | PCS |

| C-3 | double pipeling filter | 5T/H | made of sus304 stainless steel,100 mesh,inlet/outlet φ51 | 1 | PCS |

| C-4 | blending tank | 2000L | made of sus304 stainless steel,single layer,thickness of the shell is 3mm,with glass level measure(have exact scale) at the position of 135 degree,CIP cleaning ball, manhole at 45 degree,digital show termometer,60rpm vertical ring agitator, diameter of inlet/outlet is φ51,sample valve | 3 | PCS |

| C-5 | centrifugal pump | 3T/H | made of sus304 stainless steel,carbide tipped mechanical seal,inlet/outlet is φ51,pump head is 24m | 1 | PCS |

| C-6 | double pipeling filter | 3T/H | made of sus304 stainless steel,100 mesh,inlet/outlet φ51 | 1 | PCS |

| C-7 | support table for input the material | 1200*800*1200 | stainless steel bearing surface,water drainage in central,with protection fence and ladder. | 1 | PCS |

| D. sterilize and filling unit | |||||

| D-1 | UHT sterilizer | 2T/H | 2T/H,aseptic tubular type,inlet at 15~20℃,sterilize at 137℃ holding for 4S,outlet at room temperature,with self CIP cleaing system.auto water complement,auto dirt drainage,auto flow return.controlled by the PLC,Germen seimens 10 inch color touch screen. braze welding type heat exchanger.UK spirax sarco steam reduce and regulating system,Germen IFM temperature sensor. Germen Burkert hot water regulating valve,GEA pneumatic butterfly valve,shanghai yuanan pneumatic two position three way valve,Germen E+H electromagnetic flowmeter,sus304 stainless steel control box,thickness≥2.5mm,electric control system,AC contactor and breaker and relay, the brand of operation buttons are DELIXI or schneider. |

1 | PCS |

| D-2 | deaerator system | 2T/H | made of sus304 stainless steel,vaccum pump | 1 | SET |

| D-3 | homogenizer | 2T/H | 40Mpa,including starting box | 1 | PCS |

| D-4 | aseptic brick packing machine | 250ml/bag, brick shape,7500bag/h | 1 | PCS | |

| D-5 | straw sticking machine | 7500 bag/h | 1 | PCS | |

| E. water treatment system | |||||

| E-1 | water treatment system | 5T/H | four stage filter: silica sand,active carbon,micro-hole film filter,one grade RO reverse osmosis system,with high pressure pump and water storage tank | 1 | SET |

| F. CIP unit | |||||

| F-1 | semi auto CIP system | 3*1000L | SUS304,Single cleaning path,composed of 3 solution storage tank,aci/alkali and water tank,the tanks are all heat insulated,outer shell of tank is 1.5mm,inner shell 3mm thick,inlet at top and outlet at bottom,there is wind pipes in the tank for steam heating,semi auto control,the temperature is auto controlled,there is warning device at high level and low level,concentrated acid and alcali is pumped by US imported diaphragm pump;20T/H centrifugal pump, pump head is 24m, two 100L concentrated acid/alcali storage tank. | 1 | SET |

| No. | Project information | Place | Remark |

| 1 | 5 t/H Soy milk, Peanut milk Production Line | Sichuan Chengdu | Turnkey Projects |

| 2 | 100 t/D paddan drink production line | Xinjiang Urumqi | Turnkey Projects |

| 3 | 3 t/H soya-bean milk production line | Shandong weifang | Turnkey Projects |

| 4 | 100 t/D bean yogurt production line | Australia | Turnkey Projects |

| 5 | 5 t/H corn grains full-automatic drink production line | Shandong Jinan | Turnkey Projects |

| 6 | 1T/H Cereal production line | ZAMBIA | Turnkey Projects |

| 7 |

9T/H peanut and walnut milk line |

Hebei | Turnkey Projects |

| 8 | 100 t/D soy milk production line | Dalian | Turnkey Projects |

| 9 | 2T/H Soy milk production line | Ghana | Turnkey Projects |

![]()

![]()

![]()

![]()