-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

500L Plate Type Milk Pasteurization Equipment With Dairy Heat Exchanger

| Name | Plate Type Pasteurizer | Material | SUS304 Or SUS316 |

|---|---|---|---|

| Control | Automatically Control And Semi-auto Control | Voltage | According To Customer's Local Voltage |

| Sea Port | Shanghai | Warranty | 1 Year Or 12 Months |

| Highlight | milk sterilizer machine,pasteurizing milk machine |

||

plate type pasteurizer milk pasteurizer juice pasteurizer plate pasteurizer

Application: This unit is used as Pasteurizer (widely used in fresh milk, milk beverage, juice, tea, alcohol, ice cream etc.), and also pre-sterilize material when producing sterilized milk (long life milk).

Features:

This unit can be connected with separator, homogenizer, flash evaporator & degasser etc.

This machine has features of high heat recovery efficiency, low energy cost, compact design on the construction and easy operation, simple maintenance.

Ensure proper pasteurization

The temperature of the product shall be verified before and after the incubator. Only when the product is heated to an appropriate temperature and kept in the incubator for an appropriate time can the product continue to leave the pasteurizer. If this is not the case, it will automatically send a signal to the diverter valve and divert the product back to the balance tank for recirculation.

Process design and parameter

| Production capacity: | 500L-20000/H |

| Technical Parameter: | 5℃→65℃(homogenization)→85℃(15S) →5℃ |

| Control type: | Full-automatic control (PLC with touch screen), semi automatic. |

|

Equipment configuration |

A. plate heat exchanger; B. material-balance bucket; C. Hot water-balance drum; D. hot water pump; E. product pump; F. steam & water mixer; G. electricity box; H. stainless steel pipes and valves etc. I.PLC and color touch screen; |

Technical Parameter:

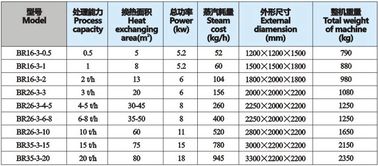

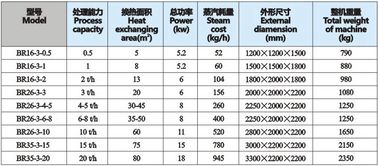

| Model | Capacity |

Heat exchane area (m²) |

Total power (kw) |

Steam consumption (kg/h) |

Dimension (L×W×H)mm |

Machine weight (kg) |

| BR16-BS-0.5 | 0.5 | 5 | 5.2 | 52 | 1200×1200×1500 | 790 |

| BR16-BS-1 | 1 | 8 | 5.2 | 60 | 1500×1500×1800 | 880 |

| BR16-BS-2 | 2 t/h | 13 | 6 | 104 | 1800×2000×1800 | 980 |

| BR26-BS-3 | 3 t/h | 20 | 6 | 156 | 2000×2000×2200 | 1080 |

| BR26-BS-4-5 | 4-5 t/h | 30-45 | 8 | 260 | 2250×2000×2200 | 1250 |

| BR26-BS-6-8 | 6-8 t/h | 35-50 | 8 | 400 | 2250×2000×2200 | 1250 |

| BR26-BS-10 | 10 t/h | 60 | 11 | 520 | 2800×2000×2200 | 1650 |

| BR35-BS-15 | 15 t/h | 75 | 11 | 780 | 3000×2200×2200 | 2150 |

| BR35-BS-20 | 20 t/h | 80 | 11 | 945 | 3300×2200×2200 | 2350 |

Technical parameter: 5℃→65℃(homogenization) →85~95℃(15S) →5℃

This unit can be connected with separator, homogenizer, flash evaporator & degasser ect. This unit is used as pasteurizer (widely used in fresh milk, milk beverage, juice, tea, alcohol, ice cream ect.) ,and also pre-sterilize material when producing pasteurized milk(long life milk).

This machine has features of high heat recovery, lower energy cost, strict design on the construction and easy operation, simple maintenance.

![]()

![]()

![]()

![]()