-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

PLC Control Mango Processing Plant Mango Pulp Processing Machine 380V 50Hz

| Place of Origin | China |

|---|---|

| Brand Name | Shanghai Beyond |

| Certification | ISO9001/CE/SGS |

| Model Number | BY-MPL |

| Minimum Order Quantity | One set/one line |

| Price | Negotiation |

| Packaging Details | PE film wrapping, or carbon steel frame packing, or wooden case packing as to clients’ requirement |

| Delivery Time | 50-100 working days upon receipt of payment and confirmed the drawings |

| Supply Ability | 50 Sets Per Season |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Mango Pulp Plant Cost | Processing Line Type | Complete Turn-key Project |

|---|---|---|---|

| Juice Yield | 50-75% | Fruit Input Brix | 10-20brix (fresh Fruit) |

| End Product Brix | 60~72Brix( For Concentrated ) | Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

| Operator Needed | About 6-20persons | ||

| High Light | 380V Mango Pulp Processing Machine,Automatic Mango Pulp Processing Machine,PLC Control Mango Processing Plant |

||

Mango processing plant mango processing machine mango pulp processing

![]()

Mango is a common tropical fruit, originating in India and Malaysia. It looks oval and light yellow. Mango is rich in protein, vitamins, minerals and other nutrients. With antioxidant effect, it can reduce the risk of cancer, prevent cardiovascular disease, reduce phlegm, delay aging, strengthen the stomach, and resist depression. Mango flesh tastes sweet and can be eaten directly or made into dried fruit. Usually, mango is processed into mango juice, brewing wine, mango vinegar, dried mango and canned mango.

Processing mango into fruit juice beverage can extend its shelf life, increase added value, increase farmers' income and enrich the fruit juice market. The production process of mango juice includes sorting, peeling and coring, softening, pulping, homogenizing, degassing, sterilization, filling and packaging, and cooling. AGICO provides a full set of mango juice production lines. High quality and reasonable price are the guarantee!

![]()

Specifications:

| Brand Name: | Shanghai Beyond |

| Model Number: | BY-MPL05 |

| Capacity | 5-50T/H |

| Raw material | Fresh Mango / pineapple |

| End product | NFC fresh juice, concentrated juice, Concentrated juice, clear juice, ,cloudy juice |

| Juice yield | 50-75% |

| Fruit input brix | 10-20brix (fresh fruit) |

| End product brix | 60~72Brix( for concentrated ) |

| Package for end product | Aseptic large bag in drum/ glass bottle/PET bottle, Gable top box/ brick shape carton |

| Certification: | ISO9001/CE/SGS |

| Main material for machines | SUS304 or SUS316 |

| Place of Origin: | China |

| Manufacturer history | More than 10years |

| Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

| Power consumption(Kw) | energy saving type, about 100-500kw, |

| Operator needed | About 6-20persons |

| Cooling water consumption | About 80-300M3 |

| Steam consumption | About 300-5000T/H, |

| Factory space needed | About 500-5000Sqm |

| Warranty | 12 months after commissioning |

|

After sales service |

Engineers available to service machinery overseas |

Mango juice production technology

The mango juice production line includes the following equipment, but not all of them are indispensable.

Fruit sorter

Fruit washing machine

Mango pulper

Vacuum degasser

Juice homogenizer

Fruit juice pasteurizer

Juice filling machine

Mango sorting process

The sorting process aims to check the raw materials to ensure the quality of mango juice. Nine mature is the best. The fruit sorter can help the staff deal with the immature, sick or rotten fruit.

The rolling mango sorter can be used to separate mango and other spherical and oval fruits. The fruit sorter can work independently or can be connected with other mango juice processing machines. The roller rod is driven by a horizontally moving chain to push the mango forward and rotate at the same time. During this process, employees can observe from all angles to find out the unqualified ones.

![]()

Mango sorter has the following advantages:

The transmission shaft is made of stainless steel with stepless speed regulation device.

The rolling bar is made of stainless steel, with smooth surface, which will not cause damage to the fruit surface.

The motor is equipped with a shield and the oil guide pipe is grounded. They contribute to the hygienic environment of fruit classification.

Mango cleaning process

The production process of this mango juice is carried out by a surf-type fruit washing machine. It is suitable for spherical and oval fruits. Under the washing of the high-pressure water pump, the fruit rolls and is washed by the rolling water. Then, they are carried into the elevator by the water flow for the next process.

Mango washing machine

Advantages of surfing mango washing machine:

The washing water can be recycled after filtration.

The circulating water pump continuously provides strong water flow to wash the fruit.

The cleaning tank is made of 1.5mm stainless steel, and the transmission shaft is made of high-quality stainless steel.

It can work alone or with other mango juice processing machines.

Mango is preheated and softened

Put mango in boiling water for 3-5 minutes, inactivate or destroy polyphenol oxidase, stabilize color and improve flavor. Preheating can also eliminate air in raw materials. In this way, we can prevent the oxidation and browning of mango, and soften the flesh of mango to facilitate pulping and juice extraction.

Peeling and pulping of mango

This mango pulper integrates mango peeling, peeling and pulping functions. As a special mango juice processing machine, it can completely remove the stone and peel of mango and minimize the loss of mango pulp.

Features of mango processing line

The processing capacity is varied from 60 tons/day to 1500 tons/day;

The line is also suitable for processing the fruits that share the similar characteristics;

Using the high efficient of mango de-stoner to improve the mango output percentage effectively;

The production process fully automatic PLC control to save labor and facilitate production management;

Low-temperature vacuum evaporation ,Maximize reserve the flavor substances and nutrients also save energy.

Tubular UHT sterilizer and Aseptic filling machine, produce high-quality aseptic juice products

Automatic CIP cleaning ,ensure the entire line equipment of food hygiene and safety requirements

![]()

Project samples:

| No. | Project information | Place | Remark |

| 1 | 5T/H Pineapple crushing | Kenya | Crushing machine |

| 2 | 2T/H pineapple juice processing line | Sri Lanka | Fresh fruit pre-processing project |

| 3 |

6t/H Beverage Production Line |

Liaoning huludao | Turnkey Project |

| 4 | 3t/H Pectin Beverage Production Line | Shandong yantai |

Turnkey Project |

| 5 | 24000 p/H PET honeysuckle Extraction Drink Pre-process Production Line | Chongqing Xiushan |

Turnkey Project |

| 6 |

12t/H beverage production line |

Henan Sanmenxia |

Turnkey Project |

| 7 | 5 t/H Aloe Beverage Production Line | Zhejiang jiaxing |

Turnkey Project |

| 8 | Fruit processing machinery | France | Fruit processing machinery |

| Flow NO | Name | Model | Specification | Qty (set) |

|

| A Fresh mango processing unit | |||||

| A-1 | Clapboard elevator | 5T/h | SUS304 frame,stainless steel clapboard, by frequency controller 20~100RPM,conveyer chain is made of antisepsis material | 1 | |

| A-2 | Air-blow washer and sorting machine | 5T/h | stainless steel centrifugal pump ; oxygen pump; speed can be adjustable,size of elevator and sorting roller is φ51, sorting table with guardrail, platform is made of stainelss steel anti-skidding Checkered plates | 1 | |

| A-3 | Brush washer | 5T/h | material is SUS304, size of the machine is 4000×2000×1400mm, imported transducer, with manual fruit pusher,at bottom with spraying device for tap water spraying | 1 | |

| A-4 | Clapboard elevator | 5T/h | motor of the machine is 3kw,with gearbox, speed is 20~100RPM adjustable, stainless steel clapboard, 4500×1100mm | 1 | |

| Subtotal: | |||||

| B Mango pulping unit | |||||

| B-1 | Pulper and destoner compound | 5T/H | SUS304 frame,speed is adjustable by transducer | 1 | |

| B-2 | Screw conveyer for fruit core | made of SUS304 stainless steel, diameter of the screw is 300mm,U shape | 3 | ||

| B-3 | Temporary storage tank | 1000L | SUS304,single layer,top mounted light view window fixture, CIP spraying ball, at bottom with flange connected outlet,with high/low level probe,4 adjustable legs | 1 | |

| B-4 | Screw pump | 10T/H | manually adjust the speed, pressure at outlet is 0.6Mp | 2 | |

| B-5 |

Tubular heater |

5T/H |

food sanitary grade. Tubular heating, with imported steam reducing valve system, temperature is manualy controled, with thermometer at outlet |

1 | |

| B-6 | Scraper type refiner | 3T/H | SUS304,stainless steel net hole ,variable frequency speed control,with adjustable outlet pressure | 1 | |

| B-7 | Buffer storage tank | 1000L | material is SUS304 stainless steel, single layer, round shape, half open type, outlet at bottom with flange connected, high/low level probe, pure water inlet | 1 | |

| B-8 | Platform for destoner,pulper and crusher | mild steel supporter, on surface with stainless steel checkered plate,dimension is 5000mm×2500mm,water drainage in central | 1 | ||

| B-9 | Platform for pulper | mild steel supporter, on surface with stainless steel checkered plate,dimension is 3500mm×2500mm,water drainage in central | 1 | ||

| B-10 | Crusher | SUS304, tooth-type, with ABB motors, with sandblasting on the appearance | 1 | ||

| B-11 | Belt press juier | 5T/H | sanitary mesh bag,SUS 304, full automatic | 1 | |

| B-12 | Double stage pulper | 5T/H | SUS304, first mesh 0.8mm , secondary mesh 0.4mm, power 18.5KW SUS 304, first stage 0.8mm mesh, second stage 0.4mm mesh, power 18.5kw |

1 | |

| Subtotal: | |||||

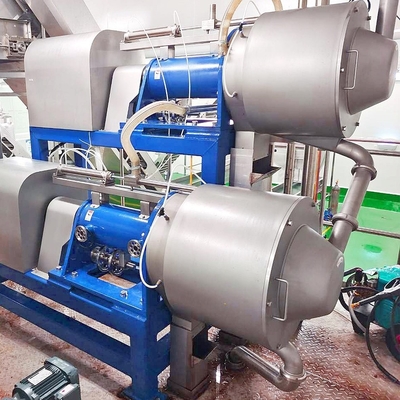

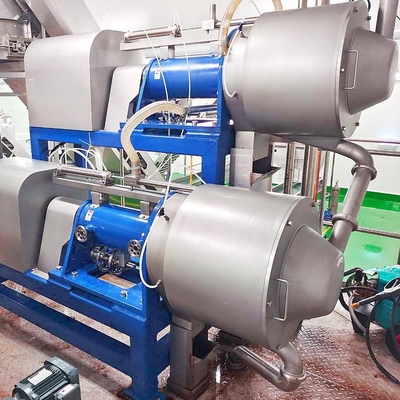

| C Evaporator and concentrating unit | |||||

| C-1 | Buffer storage tank | 3000L | Material is SUS304 stainless steel, with PU isolation, cone top, outlet at bottom with flange connected,sealed manhole,ladder,high/low level probe, sample valve, top mounted standing agitator, anti-eddy plate at bottom, digital indicator thermometer, CIP spraying ball, adjustable legs | 2 | |

| C-2 | Centrifugal pump | 10T/H | Sanitary food grade, mechanical seal,ABB motor,pump head is 36m | 1 | |

| C-3 |

Double effects forced circuit evaporator |

1.5-2T/H |

SUS304 material,full-auto PLC control, UK imported steam reduction and adjusting valve system, imported temperature sensor, differential pressure controller,use tower water for cooling |

1 | |

| C-4 | Batch storage tank | 5000L | Material is SUS304 stainless steel, single layer, digital show thermometer,sample valve,airtight manhole, ladder, high/low level sensor, standing type off-side agitator, anti-eddy plate, CIP cleaning ball, adjustable supporters | 2 | |

| C-5 | Rotary pump | 3~5T/H | use food grade rubber as gasket, inside is mirrow polished, frequency controled | 1 | |

| Subtotal: | |||||

| D sterilization and filling system | |||||

| D-1 | Tube-in-tube sterilizer | 1.5-2T/H | SUS304 stainless steel, tube-in-tube type,full-auto PLC controlled, cooling by tower water, UK imported sprirax sarco steam reducing and adjusting system, sterilization temperature is 110℃,60S | 1 | |

| D-2 | Deaerator | 1.5-2T/H | full-automatic,working with tube-in-tube sterilizer | 1 | |

| D-2 | Aseptic filler | 1.5-2T/H | Sterilized by steam, auto-control, single filling head | 1 | |

| Subtotal | |||||

| E CIP system | |||||

| E-1 | Semi-autmatic cip system | 2T×3 | External layer of CIP liquid storage tank is SUS304 stainless steel,inner is SUS316L,volume of CIP acid/alcali tanks are 2000L , with coil tubes inside of tanks for steam heating the CIP liquid, temperature is auto controled, one cleaing circuit, USA acid/alcali adding system, with small troley for acid/alcali concentrate storage barrel, one centrifugal pump(20T/h,pump head 36m) | 1 | |

| R | CIP return pump | 20T/H | food sanitary grade, self-priming, mechanical seals | 2 | |

| Subtotal: | |||||

| Total equipment price | |||||

| G project installation and others | |||||

| G-1 |

Product piping system (National standard) |

include CIP pipes, product piping system, valves, meters in the main workshop, SMS standard, include installation material for CIP system | 1 | ||

| G-2 |

Non-product system (National standard) |

include all steam piping, cold water piping, tap water and compressed air piping, not include the insulation for the pipes | 1 | ||

| G-3 |

Electric cabinets ( National standard) |

include all the electric control boxes in the main workshop, and also include the closets in the local site(made of stainless steel),include electric control box for the CIP system | 1 | ||

| G-4 |

electric distributing system ( National standard) |

include the electric cable and bridges, cables, and control system, design a master control box in central, with separate control box at exact point to control exact processing part, prepare reserved button for future additional use |

1 | ||

| G-5 | Inland freight | Send to shanghai port | 1 | ||

Condition: New

Brand name: Shanghai Beyond;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

Energy consumption: Low consumption with high efficiency

Capacity: 500-10000L/H-customized

Installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature;

Mango pulping machine

Mango pulping machine has the following advantages:

Automatically separate mango juice and residue, including stone and peel.

Mango pulping machine can work alone or together with other juice processing machines.

Meet the food hygiene standards. The parts connected with mango are made of stainless steel.

Mango juice degassing

Generally, mango juice contains a certain amount of air, which is stored in fruit or mixed in mango production process. These air will cause juice oxidation and container corrosion. By using vacuum degasser to discharge air, we can extend its shelf life. The degassing requirement is vacuum 0.65-0.75 Mpa, 90-95 ℃, 10-15 minutes.

Mango juice homogenization

After degassing, mango juice will be homogenized 2-3 times in the homogenizer under the pressure of 20-25MPa. Then crush the large particles in mango juice to 1-5 μ Below m. Homogenization can unify the granules in the juice, regulate the sediment and improve the taste of the beverage.

Mango juice sterilization

Sterilization is a necessary step to ensure the shelf life of mango juice. It can eliminate bacteria, yeast and inhibit enzyme activity in fruit juice.

AGICO mango juice sterilizer can realize high-temperature sterilization and pasteurization. The pipeline sterilizer has the characteristics of large contact area and fast heat exchange. The sterilization temperature can be adjusted from 62 ℃ to 85 ℃. It is composed of multiple tanks, suitable for small-scale production and multi-purpose.

Mango juice sterilizer

AGICO mango juice sterilizer has the following advantages:

All parts in contact with fruit are made of SUS stainless steel.

The pipe gasket is made of food grade PTFE rubber. The pipes are connected with DIN sanitary joints.

The pasteurizer is equipped with a visual temperature control system and a timing system. You can adjust the cycle and clearance time of the pump.

Mango juice filling and packaging

The juice filling machine can realize the filling and packaging of mango juice, which is a necessary step for the large-scale production and marketing of mango juice. The AGICO automatic filling machine can automatically carry out the bottle transfer, turnover, filling and drainage process. As the ideal equipment for mango juice packaging line, it has the characteristics of superior material, beautiful appearance, simple operation and convenient maintenance, and is suitable for bottles of various shapes and materials.

Mango juice filling machine

AGICO mango juice filling machine has the following advantages:

The exposed part and the part in contact with the juice are made of high-quality stainless steel or food-grade plastic.

The height adjustment device and separate feeding rod make it suitable for different bottles.

The main engine is equipped with a frequency converter, and the productivity can be adjusted within a certain range.

The whole machine is covered by a protective cover. Each working face is equipped with plexiglass escape doors.

The overload protection device can ensure the safety of the equipment.

Service flow chart

![]()