-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

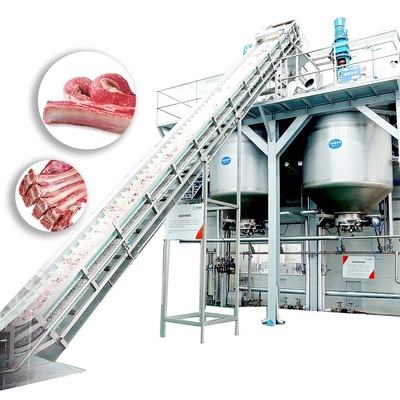

High Pressure Resistance Meat Processing Machine Automatic Control Continuously Feeding

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Warranty | 1 Year | After-sales Service | Field Installation, Commissioning And Training |

|---|---|---|---|

| Application | Chicken/Pork/Fish/Beef Livestock | Production Capacity | 70-90% |

| Power(W) | 150-200KW | Voltage | 220V/380V/415V |

| Capacity | 500KG/h-10TPH | Material | SUS304/SUS316L |

| Raw Material | Bones And Meat | Control Type | Automatic |

| Highlight | Continuously Feeding Meat Processing machine,High Pressure Resistance Meat Processing machine,Continuously Feeding meat making machine |

||

Bones&Meat Deep Processing Line

![]()

• Application Scope

The bones and meat (of Chicken/Pig/Cow/Fish etc.)deep processing lines provided by Beyond company widely used in production of meat-product,bone soup,bone flavoring essence,pet feed,flavoring seasoning etc.

• Main composed processing system

Raw bones and meat grinding system;extraction tank system;water recovery system;soup separation tank system;concentrating system;preparing and sterilizing system;Maillard reaction tank system;Finished product storage system;filling system;residue broken bones treating system;electrical control system.

• Proccedure Flow

Raw animal bones/meat→Grinding→Pre-processing→ Extracting→ Separating →

Concentrating→Blending→Drying(Filling/Packing)→Finished Product

![]()

• Introduction to Main Processing System

(A) Ossein Extraction Tank System

(1) Ossein extraction system applies to the nutrient content production using the by-products of Livestock and poultry bones as raw materials,adopting the technology of separation extraction,to extract the nutrient content in the livestock and poultry bones,such as Collagen protein,bone oil and mineral substance and so on.

(2) Advantages of ossein extraction tank system

• Short time extraction heating,high extraction efficiency;

• High pressure resistance,convenient feeding/discharging,high automatic level;

• All setting data(time/temperature)adjustable,flexible production arrangement;

• Integrated pneumatic valves group,advanced procedure,make sure clean thoroughly without sanitary dead angle;

(3) General bones ossein extraction tank design data

(take 12000L extraction tank as example)

• Volume:12000L ;

• Working pressure:inside working pressure 0.3Mpa,jacket working pressure 0.4Mpa ;

• Working temperature:134ºC ;

• Inside Material:meat;bones;water;steam;Jacket ;

• Main structure:Vertical;triple layer with insulation;top and bottom conical cover;tank body incline type;smoothly rotation;accurate location;random angle stop;stainless steel protection device at the rotary part ;

(B) High-efficiency Concentrating System

(1)Application Scope

This system is applicable in concentrating of all kinds of bone extracts solution.According to the content and physico-chemical property of bone extracts solution.We adopt the technology of membrane filtration or MVR to achieve the separating and concentrating the bones extract,and produce the bone products with high additional value.

(2)Performance Characteristics

• Stable working;energy-saving;low steam consumption;

• High concentration factor;short concentration time;

• Workable for heat sensitive material;

• High heat transfer coefficient,preventing the "Drywall" phenomenon;

(C) Maillard Compound Reaction Tank System

(1) Operating Principles

Firstly turn on the stirrer motor and reducer,under the drive of stirring shaft rotary,the scrapper stirrer;propeller,frame stirrer will all start rotary.

The Polystyrene plate connected with spring installed on the scrapper stirrer sweeps the material stick on the inner tank wall,between the level beam of frame stirrer and the shaft has 45 degrees angle,which will form pushing force.

Input solid material after the stirrer starting,otherwisethe solid material may deposit to the dead angle under the stirrer supporting bearing,the bottom sectorial scrapper can blend the material to dissolve it evenly.Afterwards turn on the steam,the steam heats the product inside tank through the jacket baffle plate and jacket covers,the condensate water is discharged through the condensate outlet.Observe the temperature of the probe,adjust the stirrer speed and direction,Turn off the steam after the reaction finisshed,open the bottom valves to discharge.After discharging,turn on the CIP cleaning ball to clean the tank inside surface,all reaction procedures finish.

(2) Characteristics

• Continuously feeding,auto discharging,high reaction efficiency;

• Compound stirring system,easy to clean,product not easy to get coked;

• Aroma recycle device can collect the aroma produced during the reaction process;

Product Specifications

| Condition | New |

| Brand name | Shanghai Beyond; |

| Type | whole processing Line/turnkey project/bones and meat processing line |

| Voltage | 220v/380v |

| Power(W) | 100-200kw |

| Weight | Different size different weight/customized |

| Dimension(L*W*H) | Different size different dimension/customized |

| Certification | CE&ISO |

| Warranty | 12 months/1 year |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Main material | SUS304 or SUS316 |

| Control type | automatic, semi-automatic |

| energy consumption | Low consumption with high efficiency |

![]()