-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Mailard Reaction Bone Broth Machine Automatic 500KG/H

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Warranty | 1 Year | After-sales Service | Field Installation, Commissioning And Training |

|---|---|---|---|

| Application | Chicken/Pork/Fish/Beef Livestock | Production Capacity | 70-90% |

| Power(W) | 150-200KW | Voltage | 220V/380V/415V |

| Capacity | 500KG/h-10TPH | Material | SUS304/SUS316L |

| Raw Material | Bones And Meat | Control Type | Automatic |

| Highlight | Mailard reaction bone broth machine,automatic bone broth machine,500KG/h bone broth machine |

||

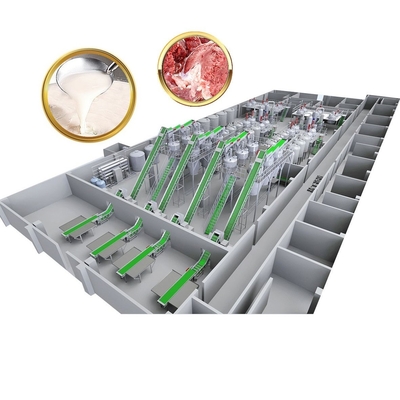

Bone soup processing line Mailard reaction system automatic bone soup production plant

![]()

• Bone soup brief introduction

Peptone in bone soup comes from collagen fibers in animal food. When collagen in animals is heated, these entangled proteins will be dissolved and rearranged. As the heat goes on, the dissolved protein will slowly dissolve into the soup. When the bone soup is cooled, these proteins are reconnected to form what we call animal gelatin.

• Introduction of bone soup production line

Specializing in providing a full set of equipment for paste soup and condiment production line, focusing on factory building service. According to the needs, we can make the production line of soup, bone soup, seasoning, soup, hot pot soup, clear soup, white soup, hot pot, dipping, sauce, sauce, essence and other finished products.

• Main composition

Raw material bone crushing and lifting system,Extraction system,condensate recovery system,Soup liquid separation system,concentration system,Blending and sterilization system,Mailard reaction system,Finished product temporary storage system,canned system,Bone residue treatment system,automatic control system.

• Proccedure Flow

Raw animal bones/meat→Grinding→Pre-processing→ Extracting→ Separating →

Concentrating→Blending→Drying(Filling/Packing)→Finished Product

![]()

• Bone soup nutrition

Bone soup is rich in animal gelatin. Animal gelatin can help repair intestinal leakage and is a good source of glycine and proline. In lean meat, the content of glycine and purine is very small.Glycine can promote digestion, help the body excrete heavy metals and accelerate wound repair; Proline can combine with vitamin C to resist atherosclerosis.

Moreover, bone soup is also rich in glucosamine, chondroitin and other mucopolysaccharides. These substances can maintain the health of our digestive system and reduce inflammation.In addition, bone marrow is also rich in vitamin A, vitamin K2, zinc, selenium, manganese and other nutrients. These substances are very helpful in maintaining a healthy bone state.

![]()