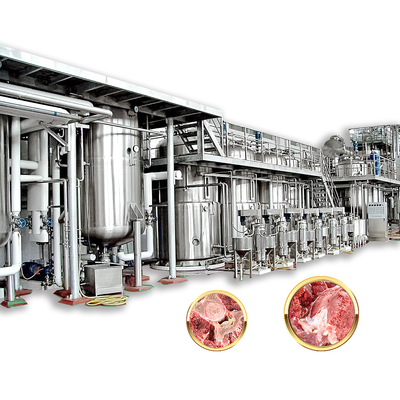

| FRESH RAW MATERIAL SYSTEM |

|

|

|

| Grinder |

|

|

1 |

| Screw pump |

10T/H |

outlet pressure 0.6MPA, frequency control motor, material SUS304, inlet and outlet size DN65 |

3 |

| Fresh raw material storage tank |

10M3 |

SUS304 stainless steel, three layer dimple jacket ,Top center frame stirring, airtight manhole, digital display thermometer, CIP cleaning ball, cylinder legs, glass tube liquid level indicator, sample valve, Capacitor type high, low level gauge interface |

2 |

| Weighing module unit |

15000KG |

Siemens brand, one unit consist of 3 pcs Shear beam type weighing module, with display instrument, bracket, signal cable, junction box |

2 |

| Centrifugal pump |

20T/H |

SUS304 stainless steel, 24 meters lift, mechanical seal |

2 |

| Temperature control system |

|

Germany Burket pneumatic Angle seat valve, JUMO temperature sensor |

2 |

| LIQUID RAW MATERIAL DOSING SYSTEM |

|

|

|

| Liquid Premix tank |

0.2M3 |

SUS304 stainless steel, single layer, Vertical cylindrical tank, airtight manhole, breather cap, digital readout thermometer, Four cylindrical legs |

1 |

| Capacitor level meter |

G1/2" |

PNP,threaded connection |

2 |

| Liquid Buffer tank |

0.2M3 |

SUS304 stainless steel, single layer, Vertical cylindrical tank, airtight manhole, breather cap, digital readout thermometer, Four cylindrical legs |

3 |

| Capacitor level meter |

G1/2" |

PNP,threaded connection |

6 |

| Scale hopper tank |

0.05M3 |

SUS304 stainless steel, single layer, Vertical cylindrical tank, airtight manhole, breather valve, digital readout thermometer, Two legs weighing module interface. |

6 |

| Weighing module unit |

100kg |

Mettler Toledo & Siemens brand, one unit consist of 1 pcs single point Weighing module, with display instrument, bracket, signal cable, junction box |

6 |

| Centrifugal pump |

10T/H |

SUS304 stainless steel, 24 meters lift, mechanical seal |

4 |

| Centrifugal pump |

3T/H |

SUS304 stainless steel, 24 meters lift, mechanical seal |

3 |

| measuring support |

|

SUS304, Measuring stacking support, stainless steel square pipe 100*50 mm, size: 5000*1200*2500(L*W*H) |

1 |

| REACTION SYSTEM |

|

|

|

|

|

10M3 |

Inner layer is SUS316L, other SUS304, three layer jacketed tank, up and down elliptical head cover, heating hollow jacketed ,Jacket is divided into upper and lower two layers, can do half a tank of materials, tank pressure - 0.1-0.3 mpa, jacketed acuities were 0.4 mpa, external thermal insulation, top center scraping wall mixing (speed 21 to 63 r/min, frequency control of motor speed, mechanical seal),Top eccentric and decentralized high-speed mixing (speed 960RPM, frequency conversion speed regulation, mechanical seal), pressure quick-opening manhole, manhole center with glass sight, relief valve, needle gauge, electric contact pressure gauges, sight glasses lamp, at the top of the CIP cleaning ball, one set at the bottom of the temperature sensor and digital display thermometer 1, tank wall mirror polishing. Three cylindrical legs, high and low capacitance liquid level gauges. |

2 |

| Capacitor level meter |

G1/2" |

PNP,threaded connection |

4 |

| Weighing module unit |

15000KG |

Siemens brand, one unit consist of 3 pcs Shear beam type weighing module, with display instrument, bracket, signal cable, junction box |

2 |

| Temperature Sensor |

PT1000 |

SUS304, 4-20mA signal output, range from 0-200℃ |

2 |

| Temperature control system |

|

UK Spirax sarco reducing valve, trap system, Chinese famous brand stop valve, steam instrument |

2 |

| Rotor pump |

10T/H |

outlet pressure 0.6MPA, frequency control motor, material SUS304, inlet and outlet size DN50 |

4 |

| Circular vibrating screen |

10T/H |

SUS304 stainless steel, solid-liquid separation (double layer), screen surface diameter 1500mm, 80 mesh aperture |

2 |

| Buffer tank |

1M3 |

SUS304 stainless steel, single layer airtight manhole, digital display thermometer, CIP cleaning ball, adjustable legs, glass tube indicator, sample valve, Capacitor type high, low level gauge interface |

2 |

| Capacitor level meter |

G1/2" |

PNP,threaded connection |

4 |

| Allocate Plate |

Ø51 |

SUS304 stainless steel, five holes, with five manual butterfly value, with water receiver pan |

2 |

| |

|

STORAGE TANK SYSTEM |

|

| Temporary storage tank |

V=20M3 |

SUS304 stainless steel, single layer airtight manhole, with decentration paddle mixer, 32 RPM,digital display thermometer, CIP cleaning ball, three cylinder legs, glass tube indicator, sample valve, Capacitor type high, low level gauge interface, Top guardrail, manhole ladder with guardrail |

2 |

| Weighing module unit |

15000KG |

Siemens brand, one unit consist of 3 pcs Shear beam type weighing module, with display instrument, bracket, signal cable, junction box |

2 |

| Capacitor level meter |

GO/2" |

PNP, threaded connection |

4 |

| Rotor pump |

10T/H |

outlet pressure 0.6MPA, frequency control motor, material SUS304, inlet and outlet size DN50 |

2 |

| Electromagnetic flowmeter |

10T/h |

4-20mA signal output, with pulse counting |

2 |

| Allocate Plate |

Ø51 |

SUS304 stainless steel, five holes, with five manual butterfly value, with water receiver pan |

2

|

|

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

![]()

![]()

![]()