-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

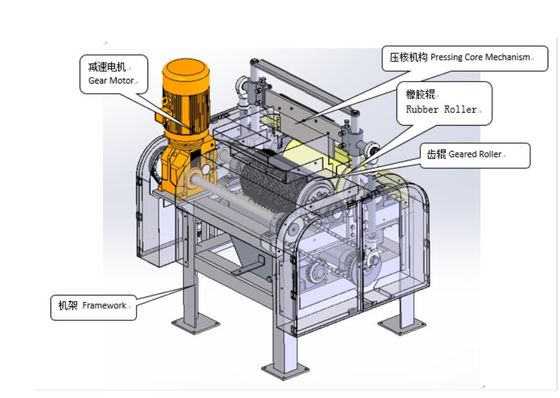

SUS316L Peaches Apricots Fruit Pitting Machine Core Remover

| Name | Fruit Destoner | Material | SUS304/SUS316L |

|---|---|---|---|

| Capacity | 5TPH-10TPH | Control Type | Full-auto/Semi-auto |

| Type | Fruit Stone Remover/Fruit Cores Destoner | Product | Fruit Puree |

| Function | Fruit Stone Removal | Spare Part | GEA,JUMO SpiraxSarco European Brand |

| Applied Fruit | Pitting Peaches, Apricots, Green Plums, And Other Stone Fruit Products. | ||

| Highlight | SUS316L fruit pitting machine,apricots fruit pitting machine,SUS316L fruit core remover |

||

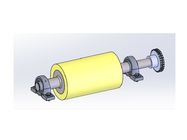

Double Fruit Pitting Machine/Destoner

1.Usage: This machine is mainly used for pitting of stone fruit such as peach and apricot at room temperature. It is one of the key equipment in the fruit pulp production line of stone fruit.

1 Fruits with hard cores, such as peaches and apricots;

2 It can effectively separate the fruit core and pulp;

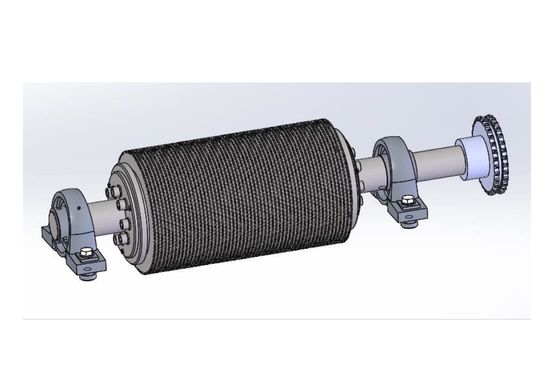

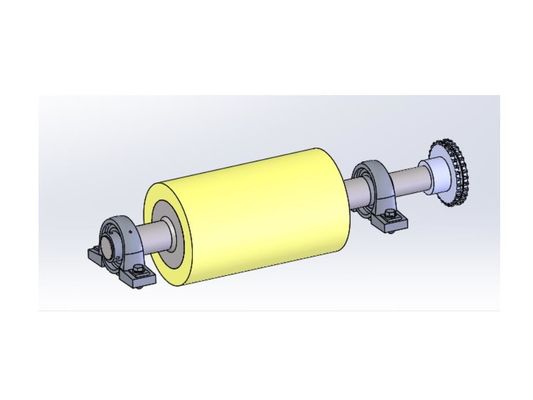

3 The meat scraper and rubber roller can be replaced according to the usage conditions, and the replacement and installation are convenient.According to the size and type of fruit, and the degree of rubber roller wear, the roller gap can be adjusted conveniently and quickly to obtain the best pitting effect.

2.Components of the equipment:

![]()

Technical parameter

|

Model |

T/h Production capacity |

KW Equipped power |

mm Outer Dimensions |

| QHJ-2 | 2 | 7.5 | 1500×1200×1600 |

| QHJ-5 | 5 | 11 | 1700×1200×1600 |

| QHJ-10 | 10 | 15 | 1700×1200×1600 |

3.Working principles

When working, the cleaned fruit enters through the feed port, and is pressed between the geared roller and the rubber roller by the reciprocating pressure core mechanism. The two rollers rotate opposite to each other, and most of the fruit pulp is pressed into the gap of the geared roller. The core is squeezed in a rubber roller with elasticity, and the comb plate digs out the pulp from the gap between the gear discs. The core with pulp enters the core washing unit to complete the core separation.

Considering that the size of the core is different in each batch, the bearing mounting screw hole of the rubber roller is designed to be waist-shaped, and there can be a certain adjustment distance to adjust the distance between the rubber roller and the tooth roller to adapt to different batches of different sizes of cores.

4.Technical descriptions

Equipment specifications: The external dimensions of the equipment are long ~ wide ~ high ~, the height of the inlet is 1200, the height of the outlet is about 700, the material of the main body of the equipment is SUS304.

The whole body material is SUS304, the bracket is made of 100*100*2.0mm stainless steel tube and SUS304 welding. The special material is heat-treated geared roller and food-grade rubber roller, the roller gap can be adjusted, frequency conversion speed regulation, organic cover, with two additional points hopper.

5.Equipment photos

![]()

![]()

![]()

![]()

![]()

![]()