-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

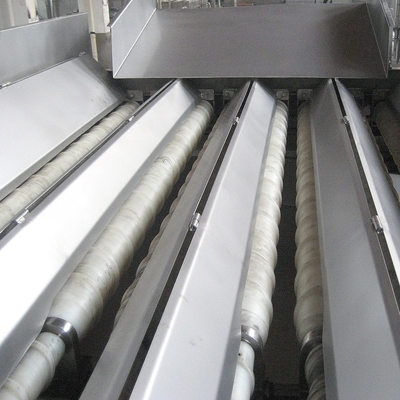

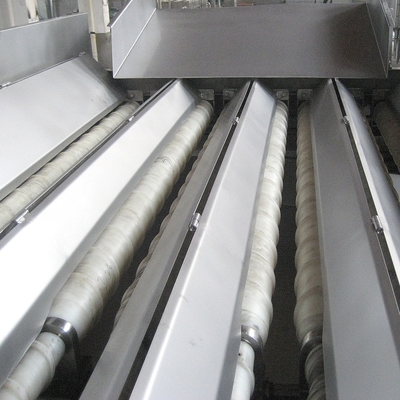

Stainless Steel Vegetables Fruit Processing Equipment With Spiral Conveyors

| Name | Spiral Conveyors | Material | Stainless Steel |

|---|---|---|---|

| Voltage | According To Customer Local Voltage | Power Consumpiton | Energy Saving Type |

| Warranty | 12 Months | Application | Used For Fruit Conveying |

| Highlight | Horizontal Vegetable Processing Line ISO9001,Fruit Processing Spiral Conveyor,Fruit Sorting Machine With Conveyor Belt |

||

![]()

Fruit processing machines Spiral Conveyors Manufacturer for fruit and vegetables

Introduction

The horizontal stainless steel screw conveyor includes simplified characters (simplified design includes "U" shaped opening or cover and "O" shaped seal), screw conveyor shaft, end cover, power rotating device and other components.

The equipment is made of high-quality stainless steel, with simple structure and stable and reliable operation. It is widely used for horizontal or inclined transportation of various dry and wet materials.

In order to prevent raw materials (such as apples, pears and other fruits) from being damaged by the blades during transportation, we welded stainless steel around the conveying blades.

![]()

| Model | Description | Transportation capacity |

Suggested power (kw) |

||

| Line speed | Capacity | ||||

| LXSS-U150 |

Outer shell and the spiral is made of SUS304 stainless steel, speed can is step-less adjustable |

50-112rpm | 4-8(m³/H) | 2-5m | 0.75 |

| 6-10m | 1.5 | ||||

| 11-15m | 2.2 | ||||

| LXSS-U200 | 50-100rpm | 7-14(m³/H) | 2-5m | 1.5 | |

| 6-10m | 3 | ||||

| 11-15m | 4 | ||||

| LXSS-U250 | 45-90rpm | 13-24(m³/H) | 2-5m | 2.2 | |

| 6-10m | 4 | ||||

| 11-15m | 5.5 | ||||

| 16-20 | 7.5 | ||||

| LXSS-U300 | 40-80rpm | 16-32(m³/H) | 2-5m | 3 | |

| 6-10m | 5.5 | ||||

| 11-15m | 7.5 | ||||

| 16-20 | 11 | ||||

| LXSS-U350 | 36-72 rpm | 26-52(m³/H) | 2-5m | 4 | |

| 6-10m | 7.5 | ||||

| 11-15m | 11 | ||||

| 16-20 | 15 | ||||

| LXSS-U400 | 36-72rpm | 30-60(m³/H) | 2-5m | 5.5 | |

| 6-10m | 11 | ||||

| 11-15m | 15 | ||||

| 16-20 | 18.5 | ||||

![]()

![]()

![]()

![]()

This equipment is a machine that uses the reducer to drive the spiral rotation to promote the material to achieve the purpose of conveying. The utility model has the advantages of simple structure, small cross-sectional area, convenient closed transportation, multi-point feeding or unloading, etc.

♦ Shell form: "O" type or "U" type;

♦ Spiral: no axis, single axis or multi axis;

♦ According to the different flow direction of materials, the following five feeding and discharging methods can be selected.

![]()

Model and parameters

Effective width: 200-400mm

Lifting angle: ≤45°

Single machine drive limit length: 1000-10000mm

Conveying speed: maximum 27m/min (adjustable)

Motor power: 0.37/0.55/0.75/1.1/1.5 /2.2Kw