-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Industrial Fruit Juice Processing Line Double Stage Pulping For Carrot Juice

| Name | Industrial Carrot Juicer Machine | Material | SUS304/SUS316L |

|---|---|---|---|

| Capacity | 1000LPH-10000LPH | Control Type | Full-auto/Semi-auto |

| Type | Double Stage Pulping | Product | Fruit Puree |

| Function | Squeezing Fruit And Vegetable Juice | Spare Part | GEA,JUMO SpiraxSarco European Brand |

| Applied Fruit | Stone Fruit/ Kernel Fruit/vegetables | ||

| Highlight | Industrial Carrot Juice Extractor Machine,Carrot Fruit Juice Extractor Machine,Double Stage Pulping Carrot Juice Extractor |

||

Fruit Juice Extractor Machine automatic industrial carrot juicer machine

![]()

The carrot juicer is suitable for automatic juicing and juicing of berries, grapefruit fruits and vegetables. Before use, turn on 220-380v voltage and start juicing.

Working principle of carrot juice machine

The screw of carrot juice machine gradually increases the bottom diameter along the direction of slag outlet, and the screw pitch gradually decreases. When the carrot Juicer pushes the carrot through the screw, it will reduce the volume of the screw cavity and squeeze the carrot. Finally, you can get carrot juice.

![]()

Carrot Juicer structure

Carrot juicer is composed of front support, feed hopper, crusher, screw, filter screen, juicer, rear support, slag tank and other parts. It is a complete spiral spindle. The motor drives the screw to work through the V-belt pulley.

Carrot Juicer

Carrot juice is a kind of vegetable juice, which takes fresh carrot as the main raw material. Carrots are rich in carotene and other nutrients. This nutrient has many functions, such as improving eyesight, beauty and enhancing immunity. Therefore, carrot juice has high commercial value. How to mass process carrots?

How to make carrot juice

Select fresh carrots → clean the peeler with a carrot brush → clean the carrots → cut them into small pieces (optional) → put the cut parts into the feed inlet → obtain carrot juice → the residue is discharged → clean the carrot Juicer after use.

You can drink the obtained carrot juice directly, or you can choose to mix and disinfect it into carrot juice beverage. We provide turnkey project of carrot juice production line.

Technical parameter

| Model | Description | External dimension(mm) | Suggested capacity | Suggested power |

| L*W*H | capacity and power varies as to different fruits | |||

| SDJ-2 | All made of sus304 stainless steel, rotating 960RPM-1350RPM | 1170*950*1250 | ≤2(T/H) | 7.5 |

| SDJ-5 | 1760*1350*1500 | 3~5(T/H) | 18.5 | |

| SDJ-10 | 1950*1550*1880 | 6~10(T/H) | 30 | |

| SDJ-15 | 2150*1550*1880 | 11~15(T/H) | 37 | |

![]()

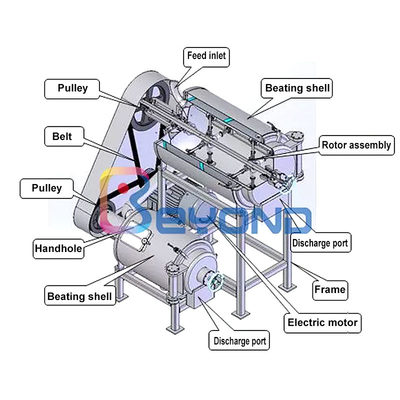

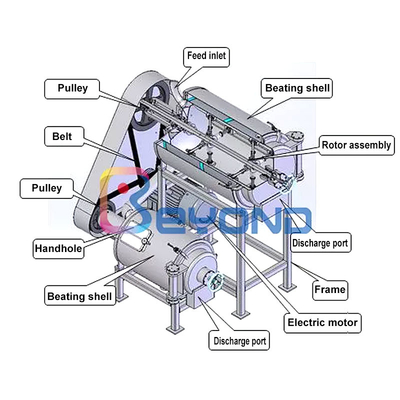

There are two pulping cavities in this equipment and they work in tandem.

When the product material enters through the screen mesh from first pulping stage feeding inlet, with the rotor’s high speed rotating, it is pressed in screen wall and has friction with it in S shape by the centrifugal force, then the fruit pulp will be discharged through the screen mesh and go to the second pulping stage inlet from the first pulping stage after accumulated in the shell, and enter into the second stage pulping through the second stage mesh screen and finally flow out through the outlet after the second pulping in the second stage.

The fruit residue will also move to the discharge outlet under the scraper force, and finally be discharged from it.

![]()

This double stage high speed pulping machine can be used to process the stone fruit after the stone has been removed (mango, peach, apricot, date), berries (kiwi, strawberry) and kernel fruit after being cooked and softened (apple, pear, pumpkin). It also can be used for squeezing the vegetable into vegetable juice after they are cut or sliced, also separating the vegetable bars, like: pepper, celery and other vegetables juice.![]()

This double stage high speed pulping machine can be used to process the stone fruit after the stone has been removed (mango, peach, apricot, date), berries (kiwi, strawberry) and kernel fruit after being cooked and softened (apple, pear, pumpkin). It also can be used for squeezing the vegetable into vegetable juice after they are cut or sliced, also separating the vegetable bars, like: pepper, celery and other vegetables juice.

![]()

![]()

![]()