-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

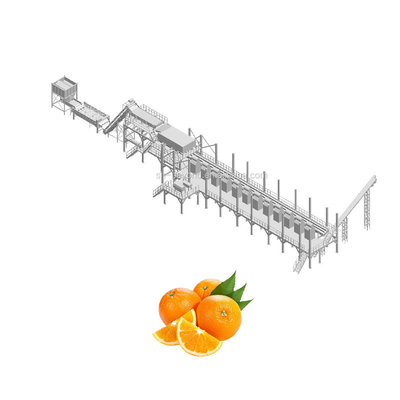

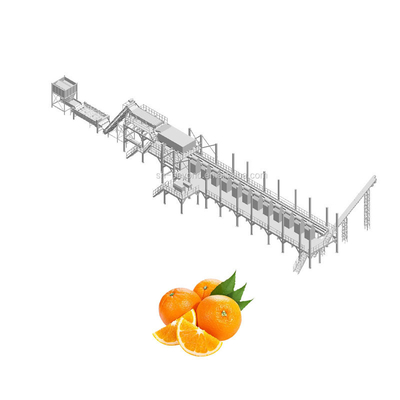

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

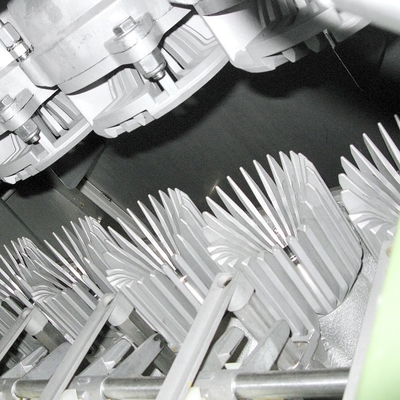

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Automatic Citrus Processing Machine For Fruit Juice

| Place of Origin | China |

|---|---|

| Brand Name | Shanghai Beyond |

| Certification | ISO9001/CE/SGS |

| Model Number | BY-DJ2000 |

| Minimum Order Quantity | 1set |

| Price | negotiable |

| Packaging Details | exporting standard package |

| Delivery Time | 65-110 working days upon receipt of payment and confirmed the drawings |

| Supply Ability | 30sets/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Capacity | 2T/D – 20T/D | End Product Package | Pre-pak Pouch, Plastic Bag, Gable Top Bag, Plastic Cup, Plastic Bottle, Glass Bottle, Sanitary Can Etc. |

|---|---|---|---|

| Raw Material | Chinese Date, Arabic Date, Iran Date,tunisia Date | End Product | Date Juice, Date Liquid Sugar, Date Honey, Date Syrup |

| Shelf Life | 6months-12months | Production Line Efficiency | 85-90% |

| Fresh Date Brix | 7-12brix | Final Product Brix | 65-75brix |

| Highlight | Automatic Citrus Processing Machine,Citrus Processing Machine For Fruit Juice,Citrus Juice Processing Machine |

||

Citrus processing machinery automatic citrus processing plant equipment

![]()

The successful and profitable production of fruit and vegetable based juices, jams and other beverages depends on a delicate balance between maintaining the quality, flavor and color associated with the source crop and complying with health standards and health and safety requirements while ensuring that production costs are as low as possible. Beyond devices, systems, know-how and services to help you achieve and maintain this critical balance.

Our global service network has specialized experts who know your industry very well. No matter when and where, we will provide you with parts and professional technical support.

![]()

The mixing line of the juicer can be of two different types:

Discontinuity: mixing of components in a tank. The working system can be automatic or manual. According to the requirements, the dosing of relevant hammer control can be completed automatically through pneumatic valve, refractometer and control PLC with automatic receiving system

Continuous automatic: equipped with online refractometer control and adjustment system, PLC control and automatic receiving.

![]()

Technical parameters

Specifications:

| Brand Name: | Shanghai Beyond |

| Model Number: | BY-AD |

| Capacity | 2-10T/H |

| Raw material | All kinds big date, small date, jujube, dry date, fresh date and hawkthorn, and Arabic date etc. |

| End product | NFC fresh juice, concentrated juice, clear juice, cloudy juice, date syrup, date honey, date paste, etc |

| Juice yield | ≥ 90% |

| Final product brix | 7-12brix(for orange juice) |

| Package for end product | Aseptic large bag in drum/ glass bottle/PET bottle |

| Certification: | ISO9001/CE/SGS |

| Main material for machines | SUS304 or SUS316 |

| Place of Origin: | China |

| Manufacturer history | More than 10years |

| Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

| Power consumption(Kw) | energy saving type, about 100-500kw, |

| Operator needed | About 6-20persons |

| Cooling water consumption | About 80-300M3 |

| Steam consumption | About 300-5000T/H, |

| Factory space needed | About 500-5000Sqm |

| Warranty | 12 months after commissioning |

| After sales service | Engineers available to service machinery overseas |

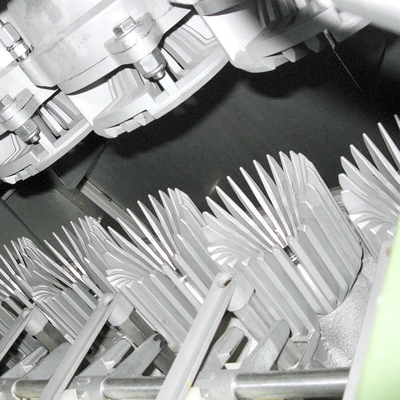

Separation, concentration and pasteurization of oranges.

If you produce orange juice, transcendental decanter centrifuges are ideal for removing pulp after extraction, while transcendental disk pile centrifuges of different types and sizes are widely used to clarify or recover the pulp of cloudy juice.

![]()

Continuous sugar dissolving line

Sugar is one of the main raw materials of fruit juice beverage industry. Dissolving granular sugar into syrup is one of the steps required to prepare fruit juice. For the continuous dissolution of sugar, a compact device installed on a self-supporting frame is proposed.

Continuous dissolution is fully automatic. The dissolver can dissolve different amounts of sugar with high concentration at high or low temperature. The dissolving device is controlled by the PLC system. In addition to other possible alarm signals, it can also control all signals of normal operation (authorization, recording and flow control, temperature and Brix).

The syrup concentration is continuously monitored by a refractometer.

The unit is equipped with a set of filtration system.

![]()

Various Fruits and Vegetables Production Lines

Complete unit of citrus processing line, include orange, lemon, pomelo, grapefruit etc.

Complete unit of Chinese date/Jujube and hawkthorn processing line

Complete unit of sea-buckthorn processing line

Complete unit of peach / apricot and plum processing line

Complete unit of pineapple / mango and other tropical fruits processing line

Complete unit of tomato processing line

Complete unit of apple/pear processing line

Characteristics:

1.During the washing procedure, under the motivity of water current and bubble, the fruits or vegetables circumvolve without fixed direction be washed thoroughly, salts and pesticide that remain on will be removed at the same time;

2. Fruits & Vegetables are pushed to the steel roll elevator by spouted water under compressed air, then turn the next processing step;

3. The Used water can be recycled after filtration;

4. The capacity of this equipment is changeable as the motor of engine is equipped with step-less shift gears.

Equipment list for 500kg date processing line for cloudy date juice, clear date juice etc.

| Flow No. | Machine Name | Size | Main technical parameter | Unit | Qty |

| A: Date Washing & Pulping system | |||||

| A-1 | Bubble spraying date washing machine |

500kg/H | SUS machine frame, eccentric vibration motor, spray cleaning device, air blower, stainless steel wind knife, removable sieve, the water collecting pan at the bottom of the machine, concentrated drainage, size:2000*1200mm | Unit | 1 |

| A-2 | Slope type spiral date precooking machine | 500kg/H | SUS 304, U shape barrel structure, insulation, with miller jacket, top opening, easy to clean, the cooking time can be adjusted by frequency conversion( no less than 10~60mins), counting based on dry date | Unit | 1 |

| A-3 | Temperature control system | Spirax Sarce pressure reducing trap valve, German temperature testing system, Burkert angle seat valve, domestic famouse brand stop valve, filter and pressure gauge etc. | Unit | 1 | |

| A-4 | Date Stone washer | 2T/H | SUS304 support, filter mesh thickness 4mm, mesh size 3mm, with ABB motor | Unit | 1 |

| A-5 | Screw pump | 2T/H | The material contact part are all made of food grade rubber, and the pressure at the outlet is 0.6MPa, frequency conversion speed regulation | Unit | 1 |

| A-6 | Single stage date pulping machine |

2T/H | SUS304, rotary speed 960rpm,mesh size diameter 1.0mm | Unit | 1 |

| A-7 | Date pulp buffer storage tank |

500L | SUS304, double layer, with ladder, adjustable feet, and cone type cover, with flange type outlet at the bottom, electrode type liquid level, digital temperature sensor. With CIP cleaning balls, inlets for pure water and material | Unit | 1 |

| A-8 | Screw pump | 2T/H | The material contact part are all made of food grade rubber, and the pressure of the outlet is 0.6MPa, frequency conversion speed regulation | Unit | 1 |

| A-9 | Rotary pump | 2T/H | The material contact part is SUS304, 0.6MPa, ftrequency conversion | Unit | 1 |

| A-10 | Pulping platform | carbon steel support, anti slip stainless steel checkered plate, steps, guard bar, central drainage,L*W*H=3500mm×3000mm×2000mm | Unit | 1 | |

| B. Filteration and clarification system | |||||

| B-1 | Date juice Storage tank | 4000L | SUS304, double layers,using PU insullation, airtight manhole, cone type cover, off-center vertical agitator ,and CIP cleaning balls on the top, digital thermometer, sight glass to show the level, adjustable feet, breathing valve, and tie valve at the bottom | Unit | 2 |

| B-2 | Rotary pump | 2T/H | The material for product contacting part is SUS304, 0.6MPa, ftrequency conversion | Unit | 1 |

| B-3 | Plate-and-frame date juice filter presser |

2T/H | Auto hydraulic cabinet type filter presser, with manual plate opening, filtering area 15m² | Unit | 2 |

| B-4 | Centrifugal pump | 5T/H | SUS304, lift 24m, mechanical seal | Unit | 1 |

| B-5 | Cloudy date juice Storage tank |

4000L | SUS304, double layers,using PU insullation, airtight manhole, cone type cover, off-center vertical agitator ,and CIP cleaning balls on the top, digital thermometer, sight glass to show the level, adjustable feet, breathing valve, and tie valve at the bottom | Unit | 1 |

| B-6 | Centrifugal pump | 5T/H | SUS304, lift 36m, mechanical seal | Unit | 1 |

| B-7 | Inorganic membrane date juice Micro filter |

2T/H | SUS 304, Inorganic ceramic membrane filter element, filter precision0.1u, with circulation pump | Unit | 1 |

| B-8 | date juice Storage tank | 4000L | SUS304, double layers,using PU insullation, airtight manhole, cone type cover, off-center vertical agitator ,and CIP cleaning balls on the top, digital thermometer, sight glass to show the level, adjustable feet, breathing valve, and tie valve at the bottom | Unit | 1 |

| B-9 | Centrifugal pump | 5T/H | SUS304, lift 36m, mechanical seal | Unit | 1 |

| C. Decolaration system | |||||

| C-1 | Resin decoloration tank for date juice |

2T/H | USS 304 maerial, composed of 2 sets 3m³ Resin tank, easy to load, and unload material, need to choose reproducible resin, resin is not included | Unit | 1 |

| C-2 | Resin regeneration tank for date juice |

3000L | SUS304, double layers with insullation, cone type cover, off-center vertical agitator, breathing valve, digital thermometer, sight glass liquidometer, manual control of temperature | Unit | 1 |

| C-3 | Acid tank | 1000L | USS 316L, single layer, cone type cover, off-center vertical agitator, breathing valve,digital thermometer, sight glass liquidometer | Unit | 1 |

| C-4 | Alkali tank | 1000L | USS 316L, single layer, cone type cover, off-center vertical agitator, breathing valve,digital thermometer, sight glass liquidometer | Unit | 1 |

| C-5 | Centrifugal pump | 10T/H | SUS316L, lift 36m, machinery seal | Unit | 1 |

| C-6 | Operating platform | SUS304, anti slip stainless steel checkered plate, steps, guard bar, central drainage, size is about L*W*H=6000mm×1000mm×1500mm | Unit | 1 | |

| C-7 | Duplex barrel type filter |

2T/H | SUS 304 stainless steel barrel type, 200mesh, nylon filter bags, duplex type | Unit | 1 |

| D. Concentrate and storage system | |||||

| D-1 | clear date juice Storage tank |

4000L | SUS304, double layers w ith PU insullation, off-center vertical agitator, blending speed, 36rpm, airtight manhole, cone type cover, CIP cleaning balls on the top , digital thermometer, sight glass liquidometer, adjustable feet, breathing valve, and tie valve at the bottom | Unit | 1 |

| D-2 | Centrifugal pump | 5T/H | SUS304, lift 36m, mechanical seal | Unit | 1 |

| D-3 | Double effect falling film date juice concentrator | 2T/H | Product contact: SUS 304, auto control evaporation , brix/temperature are all fully automatic controlled, falling film evaporator, downstream | Unit | 1 |

| D-4 | Concentrated date juice Tubular cooler | 1T/H | USS 34, tubular type, cooling agent using tower water, one stage temperature reducing 30℃ | Unit | 1 |

| D-5 | Concentrated date juice Storage tank |

2000L | SUS304,three layers, with miller jacket, PU insullation, airtight manhole, cone type cover, ladders, CIP cleaning balls on the top , digital thermometer, sight glass liquidometer, adjustable feet, breathing valve, off-center vertical agitator, and tie valve at the bottom | Unit | 1 |

| D-6 | Rotary pump | 1T/H | The material contact part is SUS304, 0.6MPa, ftrequency conversion | Unit | 1 |

![]()

![]()

![]()

![]()

The service portfolio beyond covers all the requirements of the whole life cycle of the equipment - from startup, maintenance, support and improvement to monitoring services - to achieve maximum uptime, availability and optimization.

By minimizing your total cost of ownership, we help you stay ahead of the competition.