-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Industrial Fruit Processing Equipment Stainless Steel Fruit Brush Washer 5t/H

| Material | Stainless Steel And Plastic | Speed | Adjustable |

|---|---|---|---|

| Advantage | Avoiding Chemicals Solvents Or Reagents | Application | Plastic Crates |

| Certification | CE ISO | Warranty | 1 Year |

| After-sales Service Provided | Video Technical Support | Capacity | 1-5t/h |

| Name | Fruit Brush Washer | ||

| Highlight | Stainless Steel Fruit Brush Washer,Fruit Brush Washer Processing,5t/H Washer Fruit Processing Machine |

||

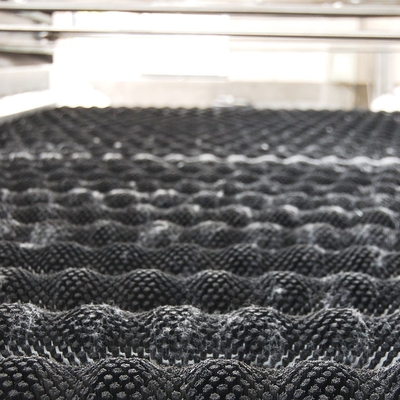

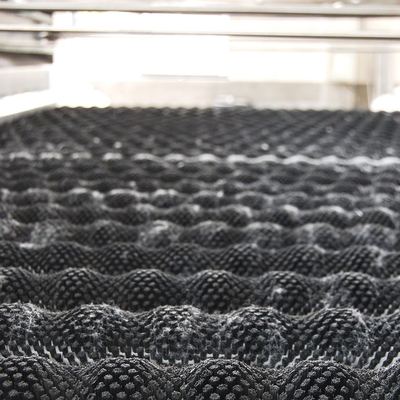

Fruit brush washing machine automatic industrial fruit brush washer

![]()

Introduction

The yond machine can not wash fruits and vegetables with less water flow, and can maintain the original

color of fruits and vegetables. The fruit and vegetable cleaning machine is suitable for cleaning all kinds

of vegetables and fruits.

Main features of brush fruit and vegetable cleaning machine:

1. The fruit and vegetable washing machine can adjust the conveying speed according to the production needs. Full automation can save labor and improve production efficiency

2. Fully meet the hygienic requirements of exported food. The raw material of the machine is 304 stainless steel,

3. The fruit and vegetable is equipped with a water circulation device, which can save water resources.

How to operate this fruit and vegetable washing machine:

1. Clean the inside of the water tank and add water; Fill the main water tank with clean water until the tank overflows.

2. Start the conveyor to make the mesh belt run normally and ensure the correct direction.

3. Start the bubble device to make the water in the water tank roll.

4. Start the spraying valve and water circulation device to spray water evenly on the mesh belt.

5. Check all operating parts to ensure normal operation after normal operation.

Brush fruit and vegetable cleaning machine is mainly used to clean vegetables, aquatic products, dates and red dates. It can also be used to clean carrots, apples, potatoes, potatoes, etc.

Main structure

The equipment is mainly composed of frame, main drive, passive drive, brush roller, reduction motor, fruit catching device, spray device, feed hopper, discharge hopper etc.

![]()

Fruit driving device(Entire machine features)

The surface of the brush roller is elliptical arc shape, which can effectively remove the residues, debris and pesticide residues on the fruit skins.

The upper part of the machine is equipped with a spray device, which can effectively wash and remove the agricultural residues, leaves and soil remaining on the surface of fruits and vegetables.The frame structure welded by stainless steel tubes and other profiles, with good overall rigidity, the whole machine in low vibration, and the transmission chain has a safety cover to ensure good safety protection performances.The equipment has a fruit catching device, effectively convey the remaining product materials to the discharge port, and then enter the next working section.

Working principles

The cleaned fruit go to the brush cleaning machine from the previous process, and come into the high-speed rotating brush roller. By means of the collisions between the fruit and the friction on fruit from the brush roller, remove the remaining agricultural residues, leaves and soil on the surface of the fruits and vegetables. The spray device on the top cleans the removed debris, several sets of brush rollers operate at the same time, and the auxiliary drive of the fruit drive device convey the product materials to the discharge port, and then go to the next process.

Technical parameter(refer to the raw fruit processing capacity)

| Model | Description |

External dimension (L×W×H)(mm) |

Suggested capacity

|

Suggested power(kw) | |

|

capacity and power varies as to different fruits |

|||||

| GMQXJ-2 | The material used is sus304 stainless steel, speed is adjustable, with water spraying device |

3000*1000*1850

|

≤2(T/H) | 1.1 | |

| GMQXJ-5 | 3000*1250*1850 | 3~5(T/H) | 1.5 | ||

| GMQXJ-10 | 3800*1500*2000 | 6~10(T/H) | 2.2 | ||

| GMQXJ-15 | 4000*1650*2000 | 11~15(T/H) | 3 | ||

| GMQXJ-20 | 4000*1900*2000 | 16~20(T/H) | 4 | ||

| GMQXJ-40 | 4500*2200*2000 | 40(T/H) | 5.5 | ||

That's all what we had talked today about the Brush cleaning and peeling machine. please contact Beyond service engineer if you got any question.

![]()

The fruit and vegetable cleaning machine can be customized according to the needs of customers. Professional mechanical engineers are engaged in the design, manufacturing, transportation, installation and commissioning of the fruit and vegetable cleaning machine, so that customers can choose at ease. Worry free can provide customers with good support in the daily use of all the important parts of the well-known fruit and vegetable cleaning machine, which can meet the needs of customers for a long time.