-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

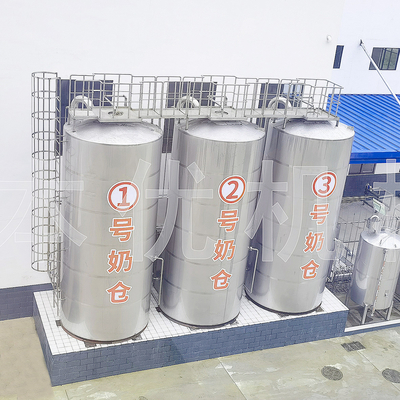

Outdoor Stainless Steel Tanks Milk Storage Silo 10000 Gallon

| Name | Stainless Steel Milk Storage Tank | Material | SUS304/SUS316 |

|---|---|---|---|

| Volume | 20m³-200m³ | Structure | Single Layer/double Layer/Insulated |

| Usage | Outdoor Silo For Storage | Product | Milk/Flour/Flour/Wine |

| Highlight | Outdoor Milk Stainless Steel Tanks,10000 Gallon Milk Storage Silo,SUS304 Milk Storage Silo |

||

10000 gallon milk silo Stainless Steel Milk Storage Tank Milk Storage Silo

![]()

Usage:

We produce hopper type flat bottom silos. It is safe to store grain, flour, rapeseed, corn and other products in stainless steel silos. Silos are mainly used for long-term storage of grain, feed, sawdust, milk (powder) and other bulk products. Properly designed flat bottomed silos or hopper silos ensure good air circulation. Silos must be durable, corrosion resistant and customized according to the facility needs of the installation site.

With the right design for your application, your product will be stored under the right conditions and maintain the best quality. Industrial silos can also be used as buffer devices in drying or purification plants.

![]()

Classification of stainless steel silos

We provide various types of storage bins and tanks made of stainless steel. We use stainless steel 304 (L) and 316 (L), and the equipment materials completely depend on the customer's needs. Stainless steel is a very strong and easy to maintain material. The silo can be well cleaned with this material, and it has high resistance to various weather conditions and mechanical damage.

Standard for stainless steel silos

Our stainless steel tanks meet high standards, and the safety and durability of our products are crucial to us. We have rich experience in tank production, including the storage of hazardous substances. Read more about how we ensure quality on the Quality and Certification page. Our engineers combine years of experience and expertise with internal computing software; The software enables tank optimization, taking into account customer requirements, material selection and compliance with specific standards.

Features of stainless steel silos

Safe storage of products,

Rapid emptying of contents (for hopper models),

Select the best material

Weather resistance,

Perfect sealing,

Advanced ventilation system,

Special components,

3D Design Technical Specifications,

Support and overall supervision of the project coordinator.

Standard attachments

a). One air tight side manhole;

b). One side mounted agitator at the bottom;

c). One PT100 thermometer, temperature range 0~100℃

d). Two CIP cleaning balls;

e). One aseptic sample valve;

f). Anti butterfly and dirt air vent;

g). Product inlet/outlet

h). Cooling medium inlet/outlet;

i). Level sensor;

j). Ladder with circle protection and protection fence at tank top

Technical parameter:

| Model | Effective volume(L) | External diameter(mm) | Total height(mm) | Heat insulation layer(mm) | Diameter of inlet/outlet |

Motor Power (kw) |

Side agitator speed(rpm) |

| BYCG-15 | 15000 | 2200 | 6500 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-20 | 20000 | 2380 | 7150 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-30 | 30000 | 2700 | 7850 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-50 | 50000 | 3200 | 9200 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-60 | 60000 | 3400 | 9800 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-100 | 100000 | 3620 | 12990 | 100 | φ51 | 5.5×2 | 960rpm |

| BYCG-120 | 120000 | 3700 | 14200 | 100 | φ51 | 5.5×2 | 960rpm |

Other volumes not specified, we could customize as to customers’ requirement.

And we will recommend manufacturing on site for the volumes that more than 120T.

![]()

![]()

![]()

![]()

![]()

![]()

Functions of stainless steel silos

Silos and tanks can be equipped with other functions such as platforms, ladders, roof railings, level measuring sensors, inspection ports, dust filters, safety plates, heating systems and insulation. Our experts will find the best solution and design the tank to meet the highest requirements.

Manufacturing and transportation of stainless steel silos

The stainless steel tanks designed and manufactured by us can adapt to local standards, such as European standards. Some tanks are specially designed for chemical storage facilities, and we also have rich experience in this area. This is just our choice. If your building codes or regulations are not listed here, please contact us. We have rich experience in the transportation of stainless steel silos. Through professional packaging, stainless steel silos can adapt to long-term sea or land transportation, so that stainless steel silos can reach customers safely.