-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

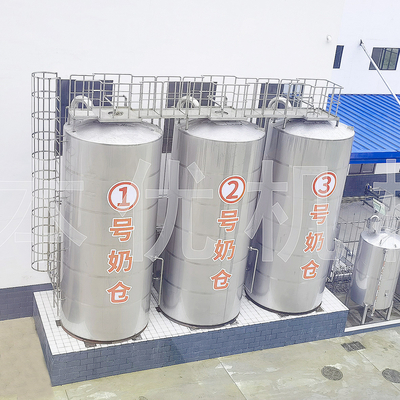

Cooling Stainless Steel Tanks Milk Silo Storage Tank Outdoor

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Milk SILO/big SILO/Flour SILO | Material | SUS304/SUS316 |

|---|---|---|---|

| Volume | 20m³-200m³ | Structure | Single Layer/double Layer/Insulated |

| Usage | Outdoor Silo For Storage | Product | Milk/Flour/Flour/Wine |

| Diameter | 15000L~120000L | Warranty | 1 Year |

| Temperature | 0~100℃ | Clean | Two Cip Cleaning Ball |

| Highlight | Milk Silo Storage Tank,Milk Cooling Stainless Steel Tanks,120000L Milk Cooling Tanks |

||

Silo storage tank milk silo milk cooling tanks milk storage tanks

To cool and store a large amount of milk, we need milk cooling tanks and milk silos. We provide a large number of high-quality vertical milk silos. These silos are specifically designed to cool and store large quantities of milk in places with limited space.

The milk silo combines rapid cooling with very low energy consumption through a cooling plate installed at the bottom of the tank. In order to generate greater cooling capacity, the milk silo is equipped with a side evaporator.

The milk silos have a capacity of 12000 to 100000 litres.

![]()

Features and advantages of milk silos

Stainless steel milk nipple with butterfly valve, equipped with a valve block and connector (other sizes are also available)

Additional control/cleaning device with control system

Automatic detergent dosage with automatic acid switching

Deep cooling circuit

Automatic cooling start

Features of milk silos

Equipped with fixed stainless steel concave chamber, with stainless steel bottom and built-in equipment

Milk outlet with butterfly valve and cover

Stainless steel cover, agitator motor mounted on top

Oval manholes in stainless steel recesses

Safety Ventilation of Concave Silo

Available in three standard colors: anthracite, dark green or gray

Cladding and coating with aluminium sheet pile profiles (hence weather resistance!)

Milk cooling tank and silo

The core of the extensive dairy product line is the milk cooling tank and silo: the most cost-effective and advanced milk cooler for dairy farmers. It is famous for its perfect surface treatment, excellent cooling performance and low operating cost.

Technical parameter:

| Model | Effective volume(L) | External diameter(mm) | Total height(mm) | Heat insulation layer(mm) | Diameter of inlet/outlet |

Motor Power (kw) |

Side agitator speed(rpm) |

| BYCG-15 | 15000 | 2200 | 6500 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-20 | 20000 | 2380 | 7150 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-30 | 30000 | 2700 | 7850 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-50 | 50000 | 3200 | 9200 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-60 | 60000 | 3400 | 9800 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-100 | 100000 | 3620 | 12990 | 100 | φ51 | 5.5×2 | 960rpm |

| BYCG-120 | 120000 | 3700 | 14200 | 100 | φ51 | 5.5×2 | 960rpm |

Other volumes not specified, we could customize as to customers’ requirement.

And we will recommend manufacturing on site for the volumes that more than 120T.

![]()

![]()

Global service of milk silos

The distributors of Benyou are distributed all over the world, and they can get support just by calling or sending email. Our dealers employ well-trained technicians to help you with troubleshooting by phone, or come to your farm in person when you need additional help.

The quality of the milk silo is high and the service is professional. The milk silo uses advanced technology to ensure that your farm continues to operate at full capacity.

Service benefits of milk silos

Trained technicians

Online training video

Experts of the factory can travel on business

Benyou has been building the milk cooling system for many years. Our efforts have paid off: we have become one of the leading suppliers in the food industry.

Our products are favored by more dairy farmers around the world. Because we provide them with the guarantee of optimal storage and cooling of farm milk. Through this excellent milk cooling system, dairy farmers can absolutely guarantee product quality, reliability, business continuity and sustainability.

![]()

![]()

![]()

![]()

Installation of silo at the bottom of hopper

Can be installed in different ways

*If the customer wants to install the silo by himself, we can provide detailed instructions, and we will answer any questions in the process as quickly as possible.

*We can also send engineers to supervise the installation process. Customers can find local workers for the installation work, and our engineers will help them during the installation process.

*If the customer needs, we can send our installation team to solve the entire installation problem.

Frequently asked questions

Q1: What certifications do you have?

A1: ISO certification, BV certification and CE certification.

Q2. What is your payment method?

A2: 30% advance payment for foreign projects, full payment.

Q3. Can you do custom design and production?

A3: The selection of prefabricated steel silos is fixed and the diameter cannot be changed. If other silos are needed, such as flour silos, cement silos and square silos, they can be customized.

Q4: What materials do you use in your steel warehouse?

A4: At the top of the warehouse, the tank body is galvanized steel plate, the diameter of the cone bottom is 4.5m, which is galvanized steel plate, and the diameter of the cone bottom is 4.5-11m, which is carbon steel plate.

Q5: What types of steel silos do you have?

A5: We mainly have cone bottom steel silos, conveyor belt bucket elevators and flour silos.

Q6: Can you provide supporting equipment? What can be provided?

A6: Yes. Cleaning equipment includes cleaning screen, vibrating screen, dedusting equipment and conveying equipment, including elevator, scraper, belt conveyor and screw conveyor.