-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Fruit Destoner Fruit Processing Equipment For Juice Manufacturing Plant

| Name | Fruit Destoner | Material | Stainless Steel |

|---|---|---|---|

| Voltage | According To Customer Local Voltage | Power Consumpiton | Energy Saving Type |

| Warranty | 12 Months | Sea Port | Shanghai |

| Highlight | fruit crusher machine,fruit and vegetable washer |

||

fruit destoner fruit stone removing machine apricot destoner peach destoner

Application

This machine is used to remove the seeds from the hard seed fruits in normal temperature, which is one of the key equipments in the stone fruits juice processing lines, such as the peach, apricot, etc.

This type destoner removes the hard stone from the fruits by two rollers (one has teeth on the surface, and the other is made of rubber) which are kept a certain gap in between;The gap between the two rollers is designed according to the feature and dimension of different fruits.

The fruits fall down to the rollers from the former procedure and then are pressed to the gap by a plate which moves up and down; the two rollers roll in opposite direction and most of the flesh is pressed to the gap of the teeth on the roller meanwhile the stones(seed of the fruit) are pressed on the stretchy roller; the flesh between the teeth on the roller will be then scratched out by a brush. The stone still with some flesh on it will be backward washed by the stone washer.

Features:

1. Can separate the fruit flesh and the stone effectively;

2. Higher efficiency and easy operation;

3. The gap between the rollers can be regulated to get a best process efficiently;

4. The rollers and the scraper can be replaced considering the status of the machine, and it is easy to do the replacement.

5.The supporter adopts high quality SUS 304 stainless steel as material to have a good integral structure;

6. The whole machine is made to be close construction, have high safety function.

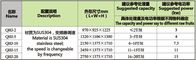

Technical parameter

| Model | Description |

External dimension (L×W×H)(mm) |

Suggested capacity | Suggested power(kw) | |

|

capacity and power varies as to different fruits |

|||||

| QHJ-2 |

Material is sus304 stainless steel; diameter of the rubber roller; the speed is changeable by frequency |

970*925*1225 | ≤2(T/H) | 3 | |

| QHJ-5 | 1320*1106*1300 | 3~5(T/H) | 4 | ||

| QHJ-10 | 2150*1375*1710 | 6~10(T/H) | 7.5 | ||

| QHJ-15 | 2450*1375*1710 | 11~15(T/H) | 11 | ||

| QHJ-20 | 2750*1375*1710 | 16~20(T/H) | 15 | ||

![]()

![]()