-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Pineapple Mango Processing Line , Fruit Juice Mango Pulp Processing Plant

| Place of Origin | China |

|---|---|

| Brand Name | Shanghai Beyond |

| Certification | ISO9001/CE/SGS |

| Model Number | BY-AL |

| Minimum Order Quantity | One set/one line |

| Price | Negotiation |

| Packaging Details | export standard package |

| Delivery Time | 50-100 working days upon receipt of payment and confirmed the drawings |

| Supply Ability | 50 Sets Per Season |

| End Product Output Brix | 65-72Brix For Concentrate | Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

|---|---|---|---|

| Raw Material | Fresh Mango Pineapple | End Product | NFC Fresh Apple/pear Juice, Concentrated Apple/pear Juice, Clear Apple/pear Juice |

| Certification | ISO9001/CE/SGS | Gurantee Time | 1 Year |

| Highlight | mango pulp machine,mango processing machine |

||

mango processing line pineapple processing line concentrate juice processing line

Description

Mango and pineapple is a famous tropical fruit, because of its delicate flesh, unique flavor, which is very popular and known as the "king of tropical fruit" fishery.

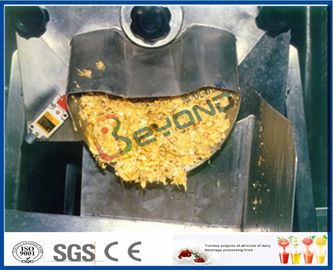

Complete plant of mango and pineapple processing equipment including following procedures, washing the fresh mango and pineapple , peeling,pulping,crushing, squeezing, enzymalisis, membrane filtrating, concentrating, sterilizing, filling process etc.

the fresh mango and pineapple is processing into the transparent juice and cloudy juice, then packing into the gable top box,aseptic bags, sterile vats and other containers, achieving the purpose of cold chain or normal temperature.

Advantages and strong points

The processing capacity is varied from 60 tons/day to 1500 tons/day.

The line Can deal with similar characteristics of fruits.

Using the high efficient of mango destoner to improve the mango output percentage effectively

Using efficient belt juice extractor to improve the juice efficiency and the output percentage of pineapple.

The production process fully automatic PLC control to save labor and Facilitate production management

Low-temperature vacuum evaporation ,Maximize reserve the flavor substances and nutrients also save energy.

Tubular UHT sterilizer and Aseptic filling machine, produce high-quality aseptic juice products

Automatic CIP cleaning ,ensure the entire line equipment of food hygiene and safety requirements

Parameters

| Raw material | Fresh Mango / pineapple |

| End product | Concentrated juice, clear juice, ,cloudy juice |

| Processing capacity | From 60tons/day to 1500 tons/day |

| Yield | 50-75% |

| Fruit consistance | 10- 20Brix |

| Product consistance | 60~72Brix |

| End package | Aseptic bag/gable top box/PET bottle |

![]()

![]()

![]()