-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

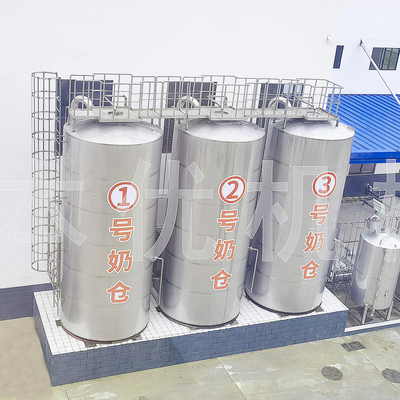

Outdoor Stainless Milk Silo Storage Tank 50000 Litres

| Name | Milk Tower Outdoor | Material | SUS304/SUS316 |

|---|---|---|---|

| Volume | 20m³-200m³ | Structure | Single Layer/double Layer/Insulated |

| Usage | Outdoor Silo For Storage | Product | Milk/Flour/Flour/Wine |

| Diameter | 15000L~120000L | Warranty | 1 Year |

| Temperature | 0~100℃ | Clean | Two Cip Cleaning Ball |

| Highlight | Stainless Milk Silo,50000 Litres Milk Storage Silo,Stainless Milk Storage Tank |

||

Milk tower outdoor stainless milk silo for sale Milk Storage Tank and Silo 10000 50000 litres

On the premise of fully mixing the reactants, the stirring device is required for the heating, cooling, liquid extraction, gas absorption and other physical change processes to achieve good results, and the external coil reactor can be designed and processed for customers.

![]()

The milk bin provides improved cooling capacity and enhanced functionality. The inner tank adopts horizontal heat transfer surface. Compared with other milk silos, the heat transfer surface discharges more heat from the milk in the same time, and its horizontal direction increases the cooling surface area, so as to achieve the best refrigeration at a lower milk volume.

Achieve maximum cooling efficiency and maintain temperature, even if the tower is not 100% full. Powerful built-in evaporator supports temperature maintenance. The milk tower provides the ultimate product protection, enabling you to provide the highest possible quality milk. It also has sanitary finishes.

A standard 4-inch vent allows the milk tower to empty faster than the previous vertical tank. This is the ideal choice for the needs of super large traditional and super large dairy farms. It has six sizes, ranging from 7000 gallons to 40000 gallons. It provides high-capacity milk cooling and storage, and the space is very valuable.

The milk tower now has a stainless steel shell and a gray finish. You can also add an insulated niche.

features

Heat transfer surface.

The installation door includes a sterile sampler.

Sensor well (horizontal).

3 "outlet connection.

3 "inlet connection.

4 "vent assembly.

Automatic adjustment heating belt on cip/ vent pipe.

Stainless steel inner shell.

Stainless steel base assembly.

Embossed aluminum housing (gray).

Stainless steel niche.

Mechanical horizontal mixing.

Perforated and removable ventilation screens.

Thermowell for recording thermometer.

Dial thermometer.

Removable local cleaning spray panel.

Optional Features

Upgrade the socket to 4 ".

Upgrade the air inlet to 4 ".

Additional 3 "or 4" inlet connections.

3-A finish

Add ons

Stainless steel housing.

3 "disc outlet valve.

CIP attachment.

CIP door.

Technical parameter:

| Model | Effective volume(L) | External diameter(mm) | Total height(mm) | Heat insulation layer(mm) | Diameter of inlet/outlet |

Motor Power (kw) |

Side agitator speed(rpm) |

| BYCG-15 | 15000 | 2200 | 6500 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-20 | 20000 | 2380 | 7150 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-30 | 30000 | 2700 | 7850 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-50 | 50000 | 3200 | 9200 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-60 | 60000 | 3400 | 9800 | 100 | φ51 | 5.5 | 960rpm |

| BYCG-100 | 100000 | 3620 | 12990 | 100 | φ51 | 5.5×2 | 960rpm |

| BYCG-120 | 120000 | 3700 | 14200 | 100 | φ51 | 5.5×2 | 960rpm |

Other volumes not specified, we could customize as to customers’ requirement.

And we will recommend manufacturing on site for the volumes that more than 120T.

![]()

![]()

![]()

![]()

![]()

![]()

FAQ:

1 ) Q: How can we visit your factory?

A: If you come from abroad, air to shanghai airport, then we can pick you up at airport.

2) Q: How do you ensure the quality of your products?

A: Our Company is a state owned enterprise with more than 16 years experience , strict operation policy is performed, advanced processing machines guarangtee the precision of all components, workers with operation license, parts get multiprocessing, transmission& electrical parts are of international famous brand. Series of test and inspection are done in the whole producing state.

3) Q: What payment methods your company accept?

A: We accept most of the payment methods , but mainly accept T/T, L/C at sight .

4) Q: How long is the warranty time for your products?

A: Our officially promised warranty time is 12 months after commissioning .

5) Q: I am new in this field,can you supply us turnkey services?

A: YES.We can supply all the system including Market Analysis/Product Analysis/Location Choice/Processing Flow Design/Equipment Layout Design/Building Design direction/Equipment mode selection/Equipment Manufacturing/Equipment Mounting/Equipment Debugging/Worker Training.

6) Q: What ' s the shipment terms and delivery time of your company?

A: Well, the delivery time depend on the quantity of your order. Usually is 20 days . For some customized machine 30 days is necessary.

7) Q: Can you supply OEM services?

A: Yes,we have our R&D team,and we have more than 400 workers with workshop area 75000 square meters.

8) Q: Do you give any Discount?

A: I will surely try my best to help you get those by the best price and good service at the same time.