-

Dairy Processing Plant

-

UHT Milk Processing Line

-

Industrial Yogurt Making Machine

-

Tomato Processing Line

-

CIP Cleaning System

-

Fruit Juice Processing Line

-

Mango Processing Line

-

Pineapple Processing Line

-

Orange Processing Line

-

Milk Pasteurization Equipment

-

Cheese Making Equipment

-

Butter Making Equipment

-

Stainless Steel Tanks

-

Fruit Processing Equipment

-

Apple Processing Line

-

Beverage Production Line

-

Multiple Effect Evaporator

-

Soft Drink Production Line

-

Meat Processing Machine

-

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well!

Erik Steen Hansen of DenmarkI am the person, who has done the trials/production using the Pineapple crusher. So far the crusher has worked very well! -

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Director Gerelkhuu of MongoliaYou are always welcome. Glad to work with your company and employees.

Insulation Coil Type Miller Jacket Stainless Steel Tanks Energy Saving SGS / CE / ISO9001

| Place of Origin | China |

|---|---|

| Brand Name | Shanghai Beyond |

| Certification | SGS/CE/ISO9001 |

| Model Number | BY-JT |

| Minimum Order Quantity | 1 piece |

| Price | negotiation |

| Packaging Details | export standard package |

| Delivery Time | 35-50 working days upon receipt of payment and confirmed the drawings |

| Supply Ability | 50 pcs per month |

| Product Name | Jacket Tank | Material | SUS304/SUS316L |

|---|---|---|---|

| Capacity | Customized | Voltage | According To Customer Local Voltage |

| Powder Consumption | Energy Saving Type | Warranty | 12 Months/1 Year |

| Seat Port | Shanghai | ||

| Highlight | chocolate melting tank,food grade tank |

||

jacket tank insulation tank coil type jacket tank miller jacket tank

Usage:

The jacket in tank can be made with dimple pad or hollow jacket or coiled pipes, which can heat or cool the product;

Special design of flow path ensures the cooling or heating medium distribute much well in the jacket, so the heat exchange efficiency is high.

Application : Widely used for preparing(heating), sterilizing, fermentation, aging, blending, cream storage etc.

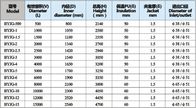

Technical parameter

| Model | Diameter | External diameter |

Height (mm) |

Insulation(mm) |

Jacket (δ) |

Diameter of inlet/outlet |

| BYDG-500 | φ500 | 800 | 2140 | 50 | 1.5 | φ38 |

| BYDG-1 | φ1000 | 1050 | 2380 | 50 | 1.5 | φ38 |

| BYDG-1.5 | φ1500 | 1180 | 2550 | 50 | 1.5 | φ38 |

| BYDG-2 | φ2000 | 1340 | 2760 | 50 | 1.5 | φ38 |

| BYDG-2.5 | φ2500 | 1420 | 2940 | 50 | 1.5 | φ38 |

| BYDG-3 | φ3000 | 1540 | 3050 | 50 | 1.5 | φ38 |

| BYDG-4 | φ4000 | 1650 | 3200 | 50 | 1.5 | φ38 |

| BYDG-5 | φ5000 | 1780 | 3250 | 50 | 1.5 | φ38 |

| BYDG-6 | φ6000 | 1900 | 3350 | 50 | 1.5 | φ38 |

| BYDG-8 | φ8000 | 2100 | 3800 | 60 | 1.5 | φ65 |

| BYDG-10 | φ10000 | 2300 | 4050 | 60 | 1.5 | φ65 |

| BYDG-12 | φ12000 | 2520 | 4450 | 60 | 1.5 | φ65 |

| BYDG-15 | φ15000 | 2540 | 4700 | 60 | 1.5 | φ65 |

![]()

![]()

![]()

![]()